Electrical system

79

Contact a specialized workshop if distilled water

must be added to the battery more frequently.

Never allow the battery to run down completely.

Recharge it once a month if necessary

.

Warning:

Battery electrolyte contains

sulphuric acid and can cause serious burns.

AVOID contact with the skin and eyes. Keep

naked flames, sparks and lit cigarettes WELL

CLEAR of batteries which are being charged.

Keep the area in which batteries are being

charged well ventilated.

Starter motor

Every 1000 hours, or once a year, clean the starter

motor thoroughly and, in particular, check if the brushes

and collector are worn.

Alternator

The alternator keeps the battery fully charged.

The alternator is a brushless model and requires no

special maintenance. However, the following precau-

tions must be observed.

1. When fitting a battery, make sure that the positive

and negative terminals are connected to the same

leads as the alternator. If you make the wrong

connection, you will short circuit the battery through

the alternator diodes. This not only discharges the

battery but also burns out the diodes and leads.

2. When connecting the battery to a charger, make sure

that the positive (+) lead of the charger is connected

to the positive of the battery, and the negative (-) to

the negative. Incorrect connection will damage the

alternator diodes and other circuit components.

3. Never run the alternator unless it is properly con-

nected. If the battery is not connected, high

voltages can build up inside the alternator that can

be extremely dangerous if the output terminal is

touched. Make sure that all connections are firm

and tight before carrying out any inspections or

tests on the electrical system.

4. Never short circuit or earth any of the alternator

terminals. This could damage the electrical system.

5. Never invert the alternator connections. The battery

and alternator earths must be of the same sign or

the alternator diodes will be damaged.

6. Always disconnect both the alternator terminals

before undertaking any electric arc welding on the

tractor.

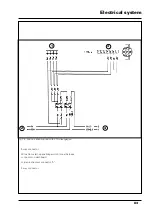

Headlights

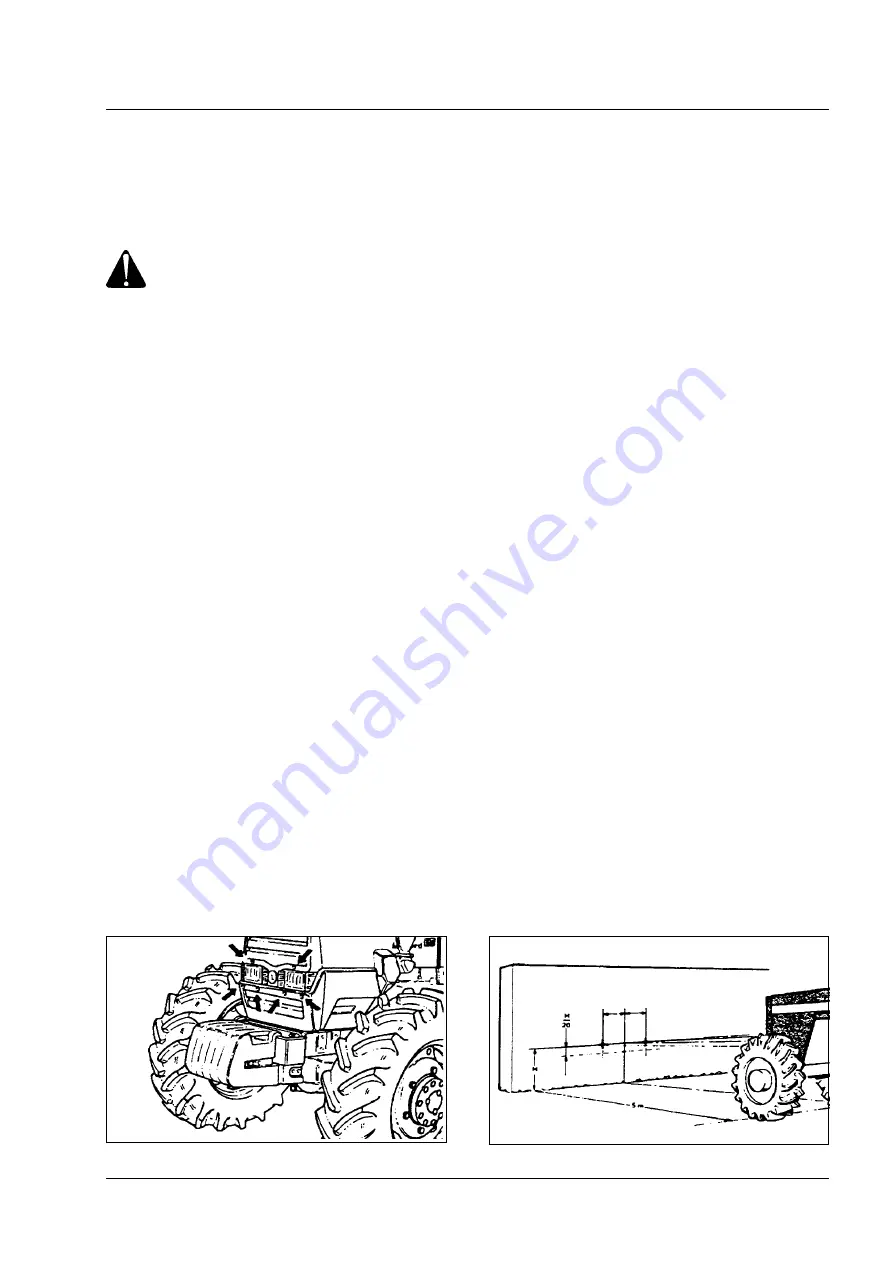

As you can use your tractor on public roads, the lighting

must comply with applicable traffic and road regula-

tions. Periodically check headlight alignment in the

following way (Fig. 74):

Halt the tractor on level ground facing a shaded wall

(preferably white). The tractor must be unloaded

and the tyres correctly inflated. Mark two crosses

on the wall in front of the tractor headlights.

Reverse the tractor 5 meters (16.4 ft) away from the

wall.

Switch on the dipped beam. The center of each

beam must be vertically aligned with the crosses on

the wall. A maximum outward divergence of 130

mm (5 in.) is acceptable.

Switch on the main beam. The line separating the lit

area from the dark area must fall below the crosses

and must be separated from their centers by at

least 1/20th of the height of the crosses from the

ground.

Adjust the headlight alignment screws to correct

alignment as necessary.

Fig. 74- Checking headlight alignment