Maintenance

63

Transmission and power circuit oil

levels

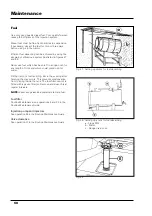

The oil levels should be between the minimum and

maximum marks on the dipstick (A-Fig.56) with the

arms fully raised: top up if necessary using oil of the

specified type.

Ensure that the transmission oil is at the correct level

since hydraulic actuators such as rams, motors,

etc.,require a certain amount of oil. The dipstick has

various notch marks

B - C - D

that indicate the level at

which the transmission oil must be when external

hydraulic circuits are used. Each mark corresponds to

5 litres of oil.

Routine Maintenance

See operations 9, 29 and 37 in the Routine Maintenance

Guide.

NOTE:

never let the oil level drop below the minimum

mark. Never use hydraulic services if the transmission

oil is at minimum level A.

NOTE:

if you use the tractor on slopes, make sure the

minimum oil level is always respected even with the

tractor on the steepest gradients it has to encounter.

NOTE:

make sure that the hydraulic services connected

to the tractor use the same type of oil as the

transmission. Mixing different oil types can lead to

damage to the system.

Clutch

Adjusting the gearshift clutch

Check the free travel of the gearshift clutch pedal at

siutable intervals.

(See operation 13 in the Routine

Maintenance Guide)

Excessive play reduces the disengaging travel of the

clutch and could prevent the gears from being

correctly meshed. On the other hand, insufficient play

could lead to abnormal wear on the disengaging thrust

bearing, overheating and rapid wear on the clutch

itself.

The free travel of the pedal (A-Fig.57) should be

between 3.5-4 cm. and is adjusted by slackening off

the nut (2) and tightening or slackening off the fork (1)

on the rod (3).

Fig. 56

A - No oil available.

B - Max. 5 liters.

C - Max. 10 liters.

D - Max. 15 liters.

Fig. 57

Fig.58

Adjusting the PTO clutch

Check to make sure that the lever is correctly adjusted

at periodical intervals. Its free travel B should be 4-5 cm.

Adjust by releasing the nut (5) and tightening or

slackening off the fork (6) on the rod (4) (Fig.58). (See

operation 14 in the Routine Maintenance Guide).