9

The MVU can be programmed to serve carbonated or

non-carbonated beverages as well as a flavor shot from

each of the beverage positions on the valve.

NOTE

On some dispensers the top button may be hidden (no

“Push” label present). In this case, the button can be

used to enter the programming mode and the button

should be set to No Water (light off). The light for the

top hidden button will be visibly when lit.

NOTE

If no entries are made for 60 seconds while in program-

ming mode, the PC board automatically saves the last

changes to the programming.

NOTE

Lights On = Plain Water

Lights Flashing Slowly = Carb Water

Lights Flashing Quickly = Flavor Shot

Lights Off = No Water

NOTE

Adjust Water Flow Rate & Syrup/Water Ratio - MVU

PROGRAMMING AND MAINTENANCE - MVU

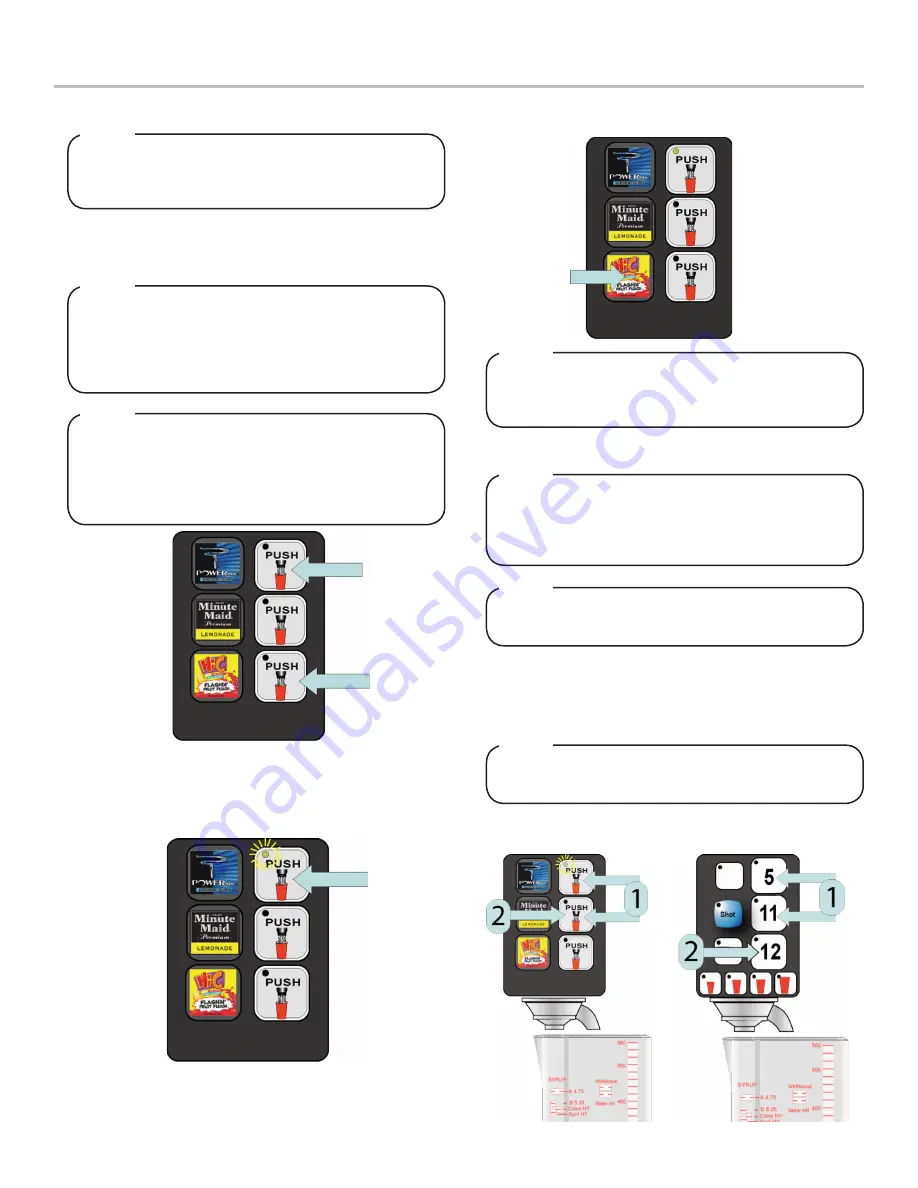

1. To enter programming mode, press both the top and bottom

brand “Push” buttons and the same time and hold for 5

seconds.

2. If the button light is off, press the Push button one time to

change to a non-carb beverage.

3. Press the same brand button again to change to a carbonat-

ed beverage (light will flash slowly).

4. Press the button one more time to change to a flavor shot

mode (light will flash quickly and water will be turned off.

The dispenser’s water flow rate is calibrated using the

on-board computer as a timer.

NOTE

The Self-Serve format uses the same two buttons to

check flow rate.

NOTE

Adjust Water Flow Rate & Syrup/Water Ratio - MVU

Ensure there is ice on the cold plate and the lines are

cold before attempting to set the flow rates on the

valves. The drink temperature should be no higher than

40°F (4.4°C) when flow rates are set.

NOTE

1. The check the flow rate, press the top and middle buttons at

the same time and hold for approximately 5 seconds.

2. The pour/cancel button will illuminate and the shot LED will

blink 5 times.

3. Place a ratio cup under the nozzle and press any brand

button. Water will pour for 4 seconds.

Self-Serve

Crew-Serve

5. Repeat process for each brand on the MVU, then press the

Save button to save the programming.

Summary of Contents for Bevariety ACIB Series

Page 14: ...14 WIRING DIAGRAMS ACIB 22 30...