- 45

-

ENGLISH

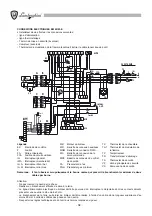

PRESSURE CURVES - B/P GAS DELIVERY

MUL

TIBLOC - 3/4” (Pi)

1

2

4

6

8

(Pt)

10

12

14

56

50

5

9

13

17

21

25

112

168

224

280

336

390

100

150

200

250

300

m

3

/h

kW

kcal/h x 10

Legend

Pi

Inlet pressure

(combustion head + gas train)

Pt

Pressure at combustion head

Pressure loss (mbars)

Thermal output

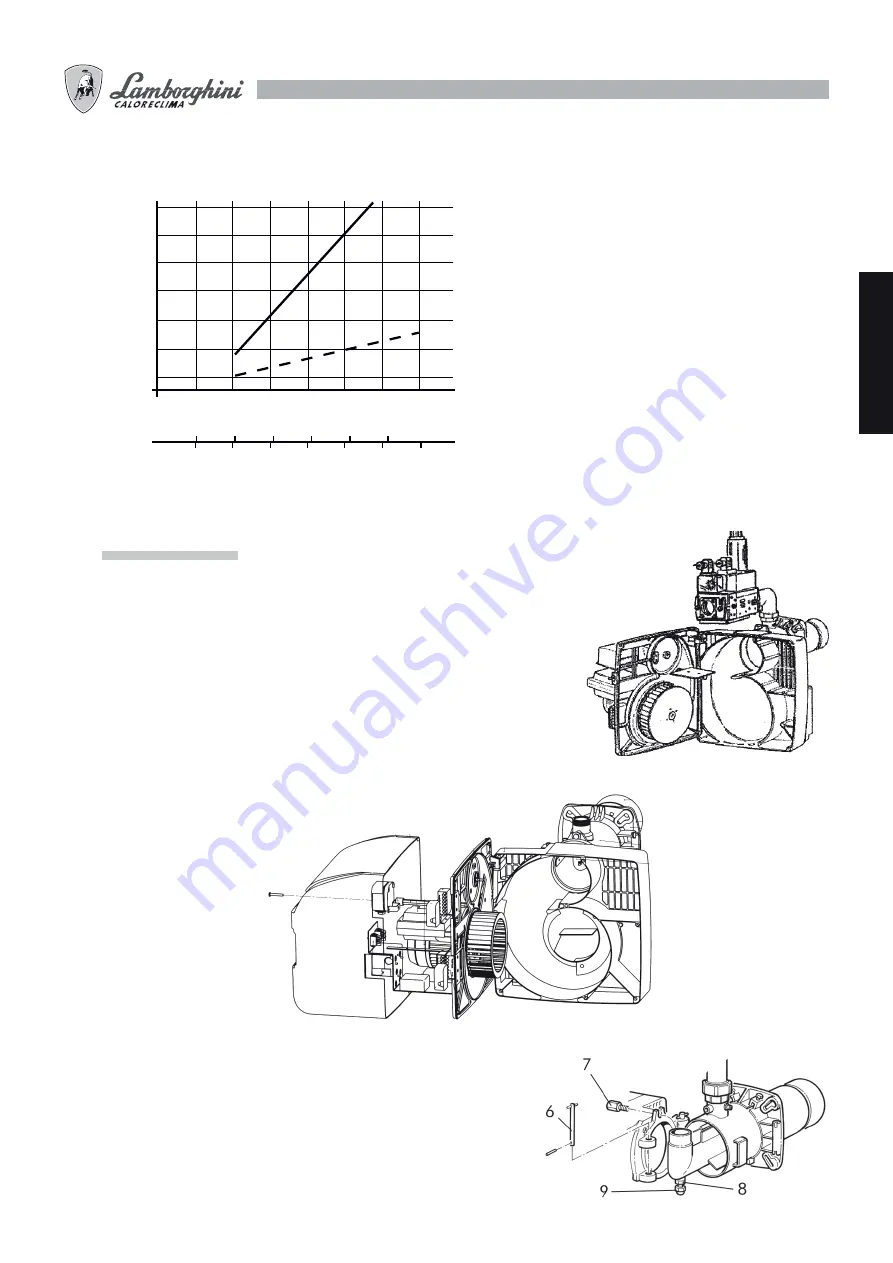

To gain access to the main components, remove the cover. Combustion

head maintenance should be made as follows:

- Unscrew the screw and remove the cover.

- Unscrew the component holder plate screws and hang the plate into

the service position.

- To gain access to the draught tube and to the electrodes, remove the

pin 6 and the screw 7, loosen locknut 8 and screw down the screw 9.

MAINTENANCE

Skilled staff has to perform yearly the following operations:

- Check the valve inside tightness.

- Filter cleaning.

- Fan and head cleaning.

- Check the position of the ignition electrode tips as well as the control electrode.

- Calibrate the air and gas pressure switches.

- Check the combustion by means of CO

2

-CO-FUMES TEMPERATURE

bearings.

- Check all the gaskets and seal tightness.

Summary of Contents for EM 40/2-E

Page 2: ......

Page 25: ...25 ITALIANO...

Page 47: ...47 ENGLISH...

Page 69: ...69 FRAN AIS...

Page 91: ...91 DEUTSCH...

Page 113: ...113 ESPA OL...

Page 115: ...115 a b c d CO2 CO2 CO2...

Page 116: ...116 119 133...

Page 120: ...120 2 n 4 3 4 5 1 A B C D...

Page 121: ...121 2...

Page 126: ...126 3 sec 3 sec LME 10...

Page 127: ...127 B 1 2 3 B H EM 35 E H H EM 40 2 E EM 40 M E H fi 1 max E E 1 E 2 E VE 2 2 14 10 13 SQN 71...

Page 132: ...132 3 A CO2 CO2 CO2 8 5 10 11 12 B P CO CO CO 0 1 160 C 220 C TPR TS B P...

Page 134: ...134 1 A B A B 2 A B C A B C 3 A A...

Page 135: ......