Lake Shore Model 642 Electromagnet Power Supply User’s Manual

Magnet System Design

2-5

2.3.6 Final

Check-Out

When all of the connections have been made the system should be tested to be sure it is operating correctly. The settings

for the magnet water should be checked to verify that they are correct for the configuration which has been installed

(Refer to Section 4.12 – Magnet Water). The maximum current setting for the magnet should be set also (Refer to

Section 2.4.2 and Section 4.11.1.)

2.4 ELECTROMAGNET

OPERATION

This section provides a brief description of the typical operation of an electromagnet. For operation of the Model 642,

refer to Chapter 4.

2.4.1

Air Gap and Pole Caps

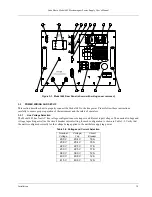

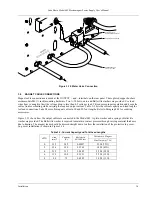

The first step in setting up a magnet for operation is to select the proper pole caps and adjust the air gap. These

parameters are determined by the size and shape of the sample, and the connections that must be made to the sample.

Generally, a smaller pole face provides a higher field within the air gap. A smaller air gap also provides a higher field.

The pole faces must be selected to accommodate the size of the sample being tested. The air gap is selected based on the

size of the sample and the other equipment being used. The curves for Field versus Current for various air gaps and pole

cap sizes for the Lake Shore Model EM4-HVA are shown in Figure 2-5. It also shows that these parameters are not

linear. This must be taken into account when operating an electromagnet. To obtain linearity, it is necessary to operate

the magnet and power supply under field control. (Refer to Section 2.4.4)

2.4.2

Maximum Current and Power

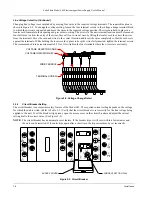

The Model 642 was designed to operate with a magnet load resistance of 0.50

Ω

, but will work with a resistance range of

0.40

Ω

to 0.60

Ω

. The resistance of a magnet will rise with a rise in temperature and this should be taken into account.

The power dissipated in the magnet is given by: P=I

2

R. If the current remains constant, the power dissipated will rise

proportionately with the rise in resistance. The Model 642 allows the user to set a maximum current limit to prevent

damage to the magnet. (Refer to Section 4.11.1.)

Figure 2-5. Typical Curves of Field vs. Current for Various Air Gaps and Pole Cap Sizes (Sheet 1 of 3)