55

19.) Grounding Connections-

Pilot arc starting generates a certain amount of

Electromagnetic Interference (Called EMI)

. This is

commonly called RF noise. This RF noise may interfere with other electronic equipment such as

the CNC controller and other equipment in the vicinity. To minimize the RF interference the

following grounding procedures should be followed when installation of the machine is

undertaken.

Drive 5/8" diameter X 10 feet long copper clad steel earth rod as close to the table as possible. It

may be necessary to weld a second rod to reach the moisture layer to achieve a proper ground.

Follow the attached instructions for proper earth ground rod testing. If multiple ground rods are

required to achieve proper grounding keep a minimum distance of 1.1 times the driven length

between driven rods.

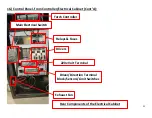

Create a main star ground on one of the table legs. The main star ground will be the only point

where all grounding wires will terminate before the earth ground rod.

The point should have good metal to metal contact and provide enough ground lead attachment

points to

eliminate the need to stack lead terminals, See Figure 2 below

:

Summary of Contents for Plasma Level 2 CNC

Page 53: ...53 17 Basic Operations Rear Door of the Electrical Cabinet ...

Page 71: ...71 21 Basic Operations Cont d The Main Display ...

Page 84: ...84 23 METHODS OF SELECTING PROGRAMS Cont d Shapes in Library 1 Shapes in Library 2 ...

Page 103: ...103 27 NESTING Cont d 4 Select the Saved File you wish to nest and press ENTER ...

Page 110: ...110 31 PROGRAMMING Cont d PROGRAMMING CODES G Codes ...

Page 111: ...111 31 PROGRAMMING Cont d PROGRAMMING CODES M Codes ...

Page 113: ...113 32 MAINTENANCE Cont d Error Code List ...

Page 115: ...115 MAINTENANCE Cont d MACHINE SETUP PARAMETERS ...

Page 128: ...128 MAINTENANCE PROCEDURE UPDATING CONTROL SOFTWARE FROM USB DRIVE Cont d 9 Push F1 ...

Page 132: ...132 FastCAM SETUP Cont d ...

Page 133: ...133 FastCAM SETUP Cont d ...

Page 134: ...134 FastCAM SETUP Cont d ...

Page 135: ...135 FastCAM SETUP Cont d ...

Page 136: ...136 FastCAM SETUP Cont d ...

Page 137: ...137 FastCAM SETUP Cont d ...

Page 138: ...138 FastCAM SETUP Cont d ...

Page 139: ...139 FastCAM SETUP Cont d ...

Page 140: ...140 FastCAM SETUP Cont d ...

Page 141: ...141 FastCAM SETUP Cont d ...

Page 142: ...142 FastCAM SETUP Cont d ...

Page 143: ...143 FastCAM SETUP Cont d ...

Page 144: ...144 FastCAM SETUP Cont d ...

Page 145: ...145 FastCAM SETUP Cont d ...

Page 146: ...146 FastCAM SETUP Cont d ...

Page 147: ...147 FastCAM SETUP Cont d ...

Page 148: ...148 FastCAM SETUP Cont d ...

Page 149: ...149 FastCAM SETUP Cont d ...

Page 150: ...150 FastCAM SETUP Cont d ...

Page 154: ...154 Laguna Tools Warranty ...

Page 156: ...156 Laguna Tools Packaging Laguna Tools BILL of LADING Example ...

Page 158: ...158 Laguna Tools Packaging Laguna Tools RMA Example ...