42

12.) Introduction to CNC Plasma Machines-

The CNC Plasma is designed to give you years of safe service. Read this owner’s manual in its

entirety before assembly or use. The advantage of the CNC Plasma machine is that it can, in most

cases, fully machine the complete job without it being removed from the table so that you have

finished parts of high accuracy that are totally repeatable. Nesting is also a valuable feature of

CNC Plasma machining that saves on waste and costs.

13.) Introduction to CNC Plasma Machines-

What is Plasma?

-

Plasma is a gas heated to an extremely high temperature and ionized so that it becomes

electrically conductive. Plasma arc cutting uses the plasma as an electrode to transfer an electrical

arc to the work piece. The heat of the arc melts the work piece, and the force of the plasma and

shield gases blow away the molten metal to cut the work piece. Different metals react differently

to plasma cutting. Carbon steel can be oxidized and is usually cut with a plasma containing oxygen

to take advantage of the exothermic process. Higher levels of oxygen in the plasma result in

higher heat and higher rates of oxidation. The result is a faster and cleaner cut. Stainless steel and

aluminum are not subject to rapid oxidation and depend entirely on the plasma’s heat for

the

cutting process. Because plasma produces much higher heat than the oxygen-fuel cutting process,

plasma can cut stainless steel and aluminum quickly and cleanly.

Summary of Contents for Plasma Level 2 CNC

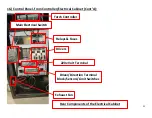

Page 53: ...53 17 Basic Operations Rear Door of the Electrical Cabinet ...

Page 71: ...71 21 Basic Operations Cont d The Main Display ...

Page 84: ...84 23 METHODS OF SELECTING PROGRAMS Cont d Shapes in Library 1 Shapes in Library 2 ...

Page 103: ...103 27 NESTING Cont d 4 Select the Saved File you wish to nest and press ENTER ...

Page 110: ...110 31 PROGRAMMING Cont d PROGRAMMING CODES G Codes ...

Page 111: ...111 31 PROGRAMMING Cont d PROGRAMMING CODES M Codes ...

Page 113: ...113 32 MAINTENANCE Cont d Error Code List ...

Page 115: ...115 MAINTENANCE Cont d MACHINE SETUP PARAMETERS ...

Page 128: ...128 MAINTENANCE PROCEDURE UPDATING CONTROL SOFTWARE FROM USB DRIVE Cont d 9 Push F1 ...

Page 132: ...132 FastCAM SETUP Cont d ...

Page 133: ...133 FastCAM SETUP Cont d ...

Page 134: ...134 FastCAM SETUP Cont d ...

Page 135: ...135 FastCAM SETUP Cont d ...

Page 136: ...136 FastCAM SETUP Cont d ...

Page 137: ...137 FastCAM SETUP Cont d ...

Page 138: ...138 FastCAM SETUP Cont d ...

Page 139: ...139 FastCAM SETUP Cont d ...

Page 140: ...140 FastCAM SETUP Cont d ...

Page 141: ...141 FastCAM SETUP Cont d ...

Page 142: ...142 FastCAM SETUP Cont d ...

Page 143: ...143 FastCAM SETUP Cont d ...

Page 144: ...144 FastCAM SETUP Cont d ...

Page 145: ...145 FastCAM SETUP Cont d ...

Page 146: ...146 FastCAM SETUP Cont d ...

Page 147: ...147 FastCAM SETUP Cont d ...

Page 148: ...148 FastCAM SETUP Cont d ...

Page 149: ...149 FastCAM SETUP Cont d ...

Page 150: ...150 FastCAM SETUP Cont d ...

Page 154: ...154 Laguna Tools Warranty ...

Page 156: ...156 Laguna Tools Packaging Laguna Tools BILL of LADING Example ...

Page 158: ...158 Laguna Tools Packaging Laguna Tools RMA Example ...