41

8.) Electrical connections for the machine-

The main power cable and has no plug fitted, as it will be dependent on your installation. Ensure

that when installing the electrical supply to the machine that 220v three-phase is supplied. It is

not possible to recommend a breaker size, as this will be dependent on the specification of the

machine that you purchase.

Note:

When wiring the machine to your electrical system, keep your cable as short as possible,

and the cable should not be allowed to run along the floor, as this will cause a trip hazard.

Note: A qualified electrician must carry out the electrical installation.

9.) Shielding and Grounding-

This section is preliminary and offers only typical shielding and grounding techniques to reduce RF

(

Electronic & Radio Frequency Noise)

noise. As with all electrical devices it is important to always

follow all local electrical codes including but not limited to the National Electrical Code.

10.) Motor Controller and other Controls-

Keep the motor controller and other controls as far from the plasma power supply as possible.

11.) Plasma Power Supply-

Place the plasma power supply and/or remote arc starter at the rear of the frame. Keep the CNC

computer controller as far from the power supply and/or remote arc starter as possible. Follow

the power supply grounding diagram found in the system manual.

Summary of Contents for Plasma Level 2 CNC

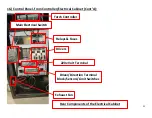

Page 53: ...53 17 Basic Operations Rear Door of the Electrical Cabinet ...

Page 71: ...71 21 Basic Operations Cont d The Main Display ...

Page 84: ...84 23 METHODS OF SELECTING PROGRAMS Cont d Shapes in Library 1 Shapes in Library 2 ...

Page 103: ...103 27 NESTING Cont d 4 Select the Saved File you wish to nest and press ENTER ...

Page 110: ...110 31 PROGRAMMING Cont d PROGRAMMING CODES G Codes ...

Page 111: ...111 31 PROGRAMMING Cont d PROGRAMMING CODES M Codes ...

Page 113: ...113 32 MAINTENANCE Cont d Error Code List ...

Page 115: ...115 MAINTENANCE Cont d MACHINE SETUP PARAMETERS ...

Page 128: ...128 MAINTENANCE PROCEDURE UPDATING CONTROL SOFTWARE FROM USB DRIVE Cont d 9 Push F1 ...

Page 132: ...132 FastCAM SETUP Cont d ...

Page 133: ...133 FastCAM SETUP Cont d ...

Page 134: ...134 FastCAM SETUP Cont d ...

Page 135: ...135 FastCAM SETUP Cont d ...

Page 136: ...136 FastCAM SETUP Cont d ...

Page 137: ...137 FastCAM SETUP Cont d ...

Page 138: ...138 FastCAM SETUP Cont d ...

Page 139: ...139 FastCAM SETUP Cont d ...

Page 140: ...140 FastCAM SETUP Cont d ...

Page 141: ...141 FastCAM SETUP Cont d ...

Page 142: ...142 FastCAM SETUP Cont d ...

Page 143: ...143 FastCAM SETUP Cont d ...

Page 144: ...144 FastCAM SETUP Cont d ...

Page 145: ...145 FastCAM SETUP Cont d ...

Page 146: ...146 FastCAM SETUP Cont d ...

Page 147: ...147 FastCAM SETUP Cont d ...

Page 148: ...148 FastCAM SETUP Cont d ...

Page 149: ...149 FastCAM SETUP Cont d ...

Page 150: ...150 FastCAM SETUP Cont d ...

Page 154: ...154 Laguna Tools Warranty ...

Page 156: ...156 Laguna Tools Packaging Laguna Tools BILL of LADING Example ...

Page 158: ...158 Laguna Tools Packaging Laguna Tools RMA Example ...