-7-

www.igmtools.com

5.4 Locating your bandsaw

Before you remove your bandsaw from the pallet,

select the area where you will use your machine.

There are no hard-and-fast rules for its location,

but below are a few guidelines.

1. There should be an area at the front and back

of the machine suitable for the length of wood

that you will be cutting. If you intend to use your

saw for scrollwork, this may not be important but

should be considered at this stage.

2. Adequate lighting. The better the lighting, the

more accurate and safely you will be able to work

3. Solid floor. You should select a solid, flat floor,

preferably concrete or something similar.

4. Close to power source and dust collection.

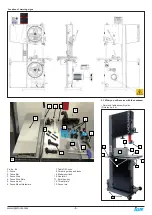

5.5 Locking the bandsaw

It is strongly recommended that the bandsaw is

never be left unattended in the unlocked

condition.

To lock the machine it is recommended that a

cover (not supplied) is made to lock the control

panel. We have supplied two concepts for locking

the panel (see below). The cover can be

made from wood or plastic.

First, push down the emergency stop. Then lock

the cover together by putting padlocks [not

included] on the two handles on the control panel.

To safeguard your machine from

unauthorized operation and accidental starting by

young children, the use of padlocks is

strongly recommended

It is possible to fit the table to the bandsaw with

one person but far easier if you have two

people, one to lift the table and one to guide the

trunion clamp studs.

The table has a reference stop bolt that is used

to quickly align the table after tilting. The stop

bolt hits the tilt-blanking disc when it is

positioned over the table tilt hole. When the tilt

blanking disc is moved away from the hole, it

allows the tilt stop bolt to pass through the table

tilt hole, and the table can be moved to the

maximum amount of tilt (-7 degrees).

Table mounted to the bandsaw

6. Assembly and set up

6.1 Assembling the rubber feet

Method 1.

Fit the rubber feet to the bandsaw prior to

removing it from the packaging.

Method 2.

1. Support the bandsaw on wooden blocks.

2. Assemble the rubber feet with the fixings

provide both at front and back of the bandsaw.

6.2 Assembling the optional mobility kit

1. Support the bandsaw on wooden blocks.

2. Fit the swivel assembly to the back of the

bandsaw with the provided bolts.

3. Fit the front wheels to the front of the

bandsaw with the bolts provided and remove

the two rubber feet that are close to the front

wheels.

Note.

Never operate the bandsaw with the

mobility kit engaged or the front wheel

assembly locking screw not engaged.

6.3 Fitting the table

Wooden safety cover

Padlock

Emergency stop switch

Plastic safety cover

Padlock

Rubber feet

Rear swivel wheel

Front wheels

Locking screw

Trunion clamp stud

Tilt stop bolt

Tilt stop bolt

Tilt blanking disc

Tilt blanking disc

Table tilt hole

Trunion clamp stud

Bandsaw supported on wooden block