-8-

www.igmtools.com

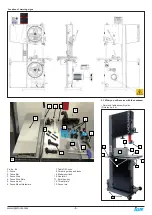

With the table fitted to the trunions, assemble

the two ratchet handles and flat washers.

How to adjust the table for square to the blade.

This will be detailed later in the manual.

6.4 Fitting the table rule

Table rule with fixings

Table with rule mounted

Attach the rule to the table with the fixings supplied.

Do not fully tighten the bolts, as the position of the

rule will have to be adjusted to suit the blade, which

will be detailed later in the manual.

6.5 Fitting the fence

1.

Fit the fence bar to the table with the screws

and spacers supplied.

Note.

The distance between the fixing holes and

the end of the bar is not symmetrical, and the end

that has the longest distance must be at the back of

the bandsaw (closest to the column).

2.

Slide the fence support onto the fence bar and

fit the fence support clamp screw.

3.

Slide the fence onto the clamping strip.

4.

Lift the fence just clear of the table and secure

it in position with the clamping screws.

Fence clamped in low position

Fence in high position

The fence support and the fence are held off

the table with a nylon-support Allen screw. This

screw ensures that the fence and the fence

support do not damage the table. The screw is

adjustable to compensate for wear.

Note

. The fence clamp screw is shown

removed.

6.6 Fitting the table insert and Fence Stopper

The machine is supplied with a removable table

insert that is held in position with a screw. The

table insert is removed when blades are removed

or fitted to the machine. The insert is made of

soft aluminium so that if the blade wanders

and contacts the insert, there is less chance

of damaging the blade. Adjusting screws are

provided to adjust the insert vertically level with

the table. The insert comes factory set, but should

adjustment become necessary, place the insert

in the table with the screw fitted. Place a straight

edge across the table and insert and adjust the

screws so that the table insert is level with the top

of the table.

Fitting the Fence Stop

The fence stopper can be used to control the

length of cut for non through cuts. To set the stop

in place, the scale should be attached into the

T-slot on top of the fence when it is on the vertical

position. The “0” on the scale should be adjusted

and set to be align up to the front tip of the blade.

Then refer to the scale, slide the fence stopper to

the desired cutting length behind the front tip of

the blade as shown in the scale, then fix the fence

stopper in place by tightening down the quick

release handle.

Rule adjustment slot

Fence support lock knob

Fence support

Fence support

Fence in low position

Lock knob

Table insert

Ratchet handle

Spacer

Fence bar

Allen key

Support Allen screw