-12-

www.igmtools.com

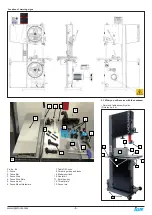

Lower blade guide shown with the table

removed for clarity

Side guides adjusted with ceramic just

behind the gullet

8. Using the bandsaw

8.1 Adjusting the fence

Although the bandsaw is usually associated

with cutting curves, a variety of straight cuts

are easily made with the saw. In fact, it is often

used to rip wood because it is much safer than

a radial arm saw and also has a smaller saw

cut, so it wastes less wood. This becomes very

important when using expensive wood where

waste must be kept to a minimum. The cut is

safer because the force of the cut is straight

down on the table; the work cannot be pulled

back or kicked back, which sometimes happens

with table or radial arm saws. The bandsaw

can also cut very thick stock, which the radial

arm, or table saw cannot do. The disadvantage

of cutting with the bandsaw is that the surface

finish of the cut is not as good as with the

table or radial arm saw. This can be overcome

to a great degree by using the Resaw king

blade from Laguna. The blade has many of

advantages such as superior surface finish to

the cut, thin kerf (low wood waste), it can be

re-sharpened, will cut hard woods and has a

long life.

Ripping

Ripping is a cut made with the grain of the

wood. The four most common cuts made with

the grain of the wood are rip, bevel, taper

and resaw cuts. There are two frequently

used techniques for making straight bandsaw

cuts. One technique is to use a single point

to guide the work. The rationale for using a

single point is that the saw may tend to cut at

a slight angle. This is called drift or lead. The

single point allows the operator to compensate

for the drift and cut the wood straight. With

a little practice, you will obtain satisfactory

results using this method. However, you now

own a real bandsaw, so this method is not

recommended. Another method is to use the rip

fence as a guide. Once set up, this takes the

guesswork out of cutting, reduces the stress

on the operator and is a must for volume work.

Once you have mastered the setup procedure,

you will tend to use the single point method less

and less.

Adjusting the fence for drift

Method 1

1. Make a straight pencil line on the edge of a

board.

2. Feed the wood into the blade cutting next

to the pencil mark. If the blade is drifting, you

will have to compensate by angling the wood

to keep the cut straight.

3. Stop the cut in the middle of the wood and

mark (with pencil) the angle on the table. This

is the angle of drift, and you will have to set the

fence to the pencil line.

4. To adjust the fence, loosen the clamp bolts

that attach it to the cast bracket. Move the

fence so that it lines up with the pencil mark on

the table and retighten the clamp screws.

Method 2

1. Set the fence parallel with the blade by

loosening the clamp screws that hold it to the

cast bracket. It is not important that it is exact

because you will be readjusting later in the

procedure.

2. Using a piece of scrap wood, make a cut

while holding the wood against the fence. Stop

the cut in the middle of the wood.

3. Look at the position of the back of the blade

within the saw cut. The back of the blade

should be in the center of the slot, but you will

probably find that it is closer to one side.

4. Slightly loosen the clamp screws and adjust

the fence to compensate. Repeat steps 2, 3

and 4 until the blade is centered.

Note

: You may have to do several fine

adjustments, and it is better to do several small

adjustments until you become skilled at the

procedure. Once you have mastered the

process, it should only take a minute to perform

the adjustment.

Note

: Each blade has a slightly different drift,

and each time you change a blade, you must

check and readjust if necessary.

Note

: It is worth taking the time to set the fence

accurately as it will save frustration and

enhance the performance of your machine.

Adjusting the table rule

There is a rule that is fitted to the side of the

table and can be used as a quick guide on the

distance that the fence is from the blade.

Note

. The rule will have to be adjusted each

time the fence is adjusted for drift, as this will

change the distance the fence is from the blade.

Once the fence has been adjusted for drift:

1. Lock the fence to the rail.

2. Measure the distance from the front of the

blade to the fence.

3. Check the distance indicated on the rule.

4. Loosen the clamp bolts and adjust the rule.

5. Tighten the clamp bolts and recheck.

Fence position

Fence in low position

Fence in high position

The aluminum fence can be used in two height

positions (high and low). The low position is

handy for cutting thin wood and is used where

the fence in the high position would make it

awkward to complete cuts. The fence in the

high position is used for supporting tall work.

Changing the fence height.

1. Loosen the clamp screws that are located on

the cast bracket.

2. Slide the aluminum fence off the cast iron

bracket.

3. Slide the aluminum fence back onto the

bracket using the second slot and retighten the

clamp screws.

Table rule

Adjustment slot

Correct

Adjust