-14-

www.igmtools.com

forward off the front of the wheels. Therefore,

be careful not to put too much pressure on the

stone. When doing this, it is also important that

the upper guides be positioned right above

the stone.

The blade has teeth and extreme caution

must be exercised, as your hands will

be very close to them.

Causes of blade breakage

1.

Excessive blade thickness in relation to the

flywheel diameter.

2.

Defective welding.

3.

Incorrect tension, particularly if the blade is

over tensioned; the tension spring no longer

fulfils its function.

4.

After use it is recommended that you slacken

the tension, especially overnight. (Be sure to

place a clearly visible note on the machine that

you have done this.

5.

Misalignment of the flywheels.

6.

Irregularity of flywheel surface, for instance,

an accumulation of sawdust while cutting

resinous materials.

You can correct these problems by readjusting

the machine, changing the way you operate it

or by changing the blade. Try only one change

at a time.

Causes of blade dulling.

1. Poorly set side guides or rear thrust guide.

2. Poor tracking.

3. Wrong blade selection. If the blade is too

narrow, it will flex more easily and decrease the

quality of the cut. The blade should also have

the correct pitch and width.

4. The tooth pitch is too fine (too many teeth

per inch).

5. Certain woods will dull a steel blade very

quickly, especially tropical hardwoods (teak,

koa, etc.). Other woods with a high silicon

content will also dull the blade quickly; even a

cut as short as 152,4mm will cause damage to

the blade.

6. On certain exotic woods, the ends have been

painted. This is done to control the drying.

The paint is very abrasive and will dull the

blade as you cut through it. It is recommended

that you cut the painted ends off your wood.

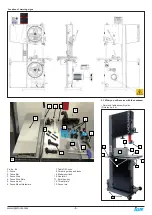

Using a radius chart.

Until you become well acquainted with your

saw, it is best to use the contour (radius) chart

to determine which size blade to use for a

specific application. Radius charts can be found

in many woodworking books, magazine articles

and on blade boxes. They differ slightly from

one another but are good as rough indicators of

how tightly a curve can be cut with a particular

blade. Each blade saw and operator is different,

so it is impossible to make a truly accurate

chart. A blade can cut continuously without

backtracking any curve that has a radius as

much as or more than is shown on the chart.

For example: a 3/16“ blade will cut a circle with

a 5/16“ radius or a 5/8“ diameter. To test if a

3/16“ blade would work for a particular curve,

place a dime (roughly 5/8“) over the pattern.

The 3/16“ blade can cut a curve bigger than the

dime, but not smaller. You can use everyday

items such as coins or a pencil to determine

which blade to use. A quarter is the size of the

tightest cut that can be made with a 1/4“ blade.

A dime is the size of the tightest curve that can

be cut with a 3/16“ blade. A pencil eraser is the

size of the tightest turn that you can make with

a 1/8“ blade. After a while you won‘t even need

an object to size the possible curve of a blade

because you will have become familiar with this

process. There are options to matching the

blade to the smallest curve pattern. If there is

only one very tight cut, it may be best to use a

turning hole, a relief cut, successive passes or

to change the blade. If you have a lot of cutting

to do, you can use a wider blade for the bigger

curves and then switch to a narrower blade for

the tighter curves. Changing the blades can

often save cutting and finish time. The chart

above is only a rough guide and is

not to scale

,

but from the information you can construct your

own guide.

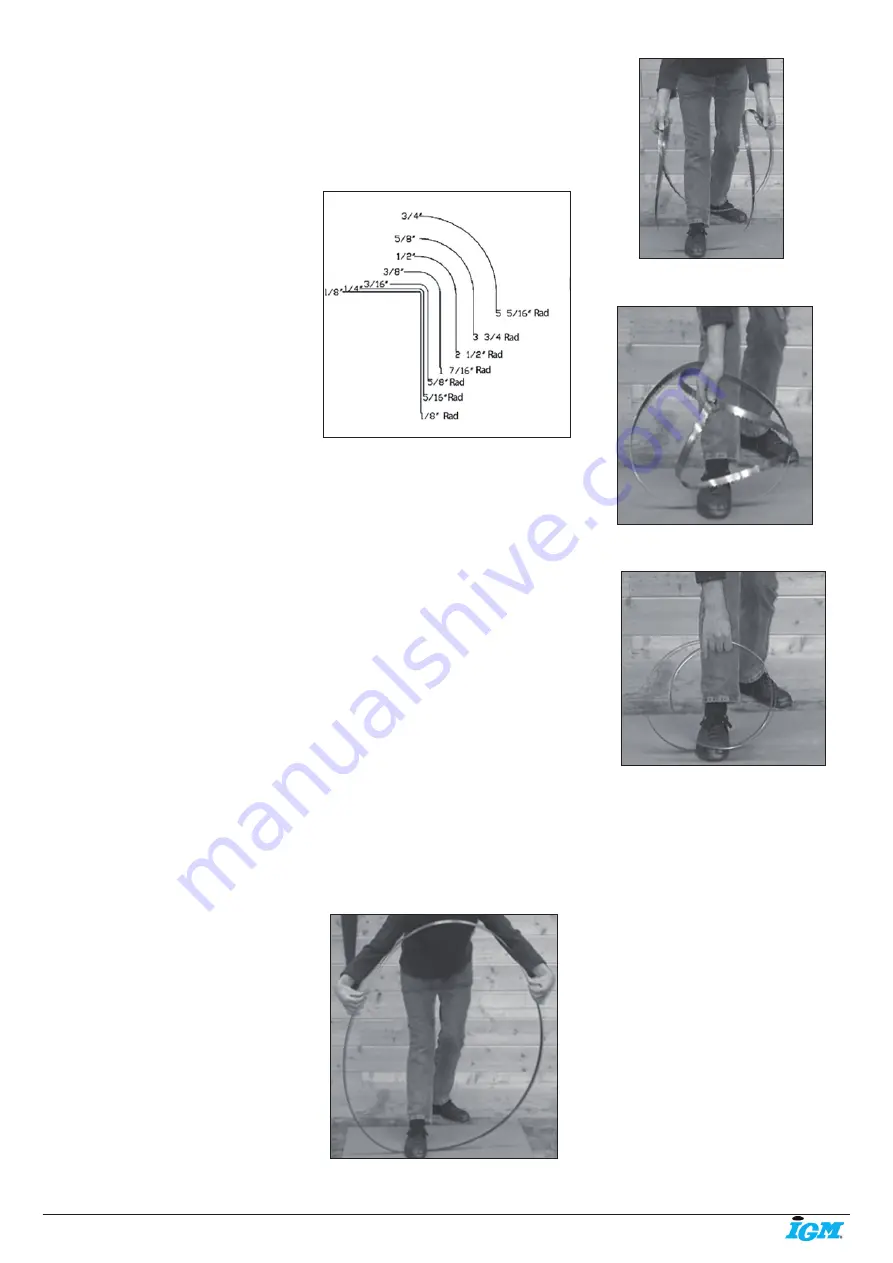

8.3 How to coil a bandsaw blade

Without a doubt it is more difficult to explain

how to coil a bandsaw blade than it is to

actually do it. Nevertheless, below are easy-to-

follow instructions on folding a blade.

Method 1

While wearing a jacket or long-sleeved shirt and

gloves, hold the blade in front of you in one

large loop, with the teeth facing towards you.

Place your foot on the blade, holding it on the

ground. Grasp the blade with both hands, with

your thumbs to the outside, at approximately

the 10 o‘clock and 2 o‘clock positions (Step 1).

Slowly twist the top of the blade away from

your body (Step 2). Bring your hands together

to form two loops while folding down (Step 3).

Continue rotating the blade until you form three

loops.

Note

. It is recommended that the blade be

placed on material that will not damage the

blade teeth (wood or cardboard). Your foot

is there to give stability and not to clamp the

blade, so do not exert excessive force, or the

teeth/band may be damaged. The photographs

are shown without gloves to enable the hand/

thumb position to be shown. Gloves must be

worn, as the blade could cause injury.

Step 1

Step 2

Step 3

Done

Note: In order to show the hand/thumb position

of the man in the photographs, he is not

wearing gloves, but gloves MUST BE WORN as

the blade could cause injury.

Method 2

There is another variation of this that works well

with small blades but simply is not

possible for larger bandsaw blades, unless

you‘re very big and strong. This method works

the same as the method above, but rather than

holding the blade with both hands, grasp

the blade at the top while holding the bottom of

the blade with your foot (teeth still facing

away from you). Grasp the blade with your

hand, twisting your arm such that your elbow is

facing away from your body (Step 1). Turn the

palm of your hand toward your body about

180 degrees and then continue turning while

pushing down on the blade (Steps 2, 3 and 4).

The blade will fold down upon itself into three

circles, lying flat on the ground (Done).

Blade width

Cutting Rad