-16-

www.igmtools.com

9. Maintenance

All tools and machines require regular

maintenance, and the bandsaw is no exception.

This section details the general maintenance

and care of your bandsaw. In general, we

recommend that you only use a Teflon-based

lubricant on the bandsaw. While regular oil

attracts dust and dirt, Teflon tends to dry and

has fewer tendencies to accumulate dirt and

sawdust on your machine.

Cleanliness and tire maintenance.

One of the major concerns in regards to the

maintenance of the bandsaw is how clean the

tires are. As the saw cuts, some sawdust lands

on the tire of the lower wheel. As the wheel

rotates, the sawdust becomes compressed on

the tire. This is especially true for woods such

as pine. The compressed sawdust could have

a negative effect, such as vibration, short blade

life and drifting of the blade. A brush contacts

the lower wheel and helps to prevent buildup.

You should inspect the tires regularly to check

that buildup is not happening, especially the

lower wheel. The tires are made of rubber

and wear just like car tires. They wear in the

middle, which causes a concavity in the tire.

The deformation makes it hard to track the

blades, and for this reason it is important to

maintain the original shape of the tire. The best

way to clean the tire surface and maintain the

original shape is to sand it with sandpaper.

The old tire surface often hardens and glazes

over and should be redressed occasionally.

This can be done by sanding the wheel with

100-grit sandpaper. This will take off a little of

the rubber and expose new rubber, which is

desirable. Rotate the wheels by hand with the

blade removed.

Guides

The ceramic side and back guides should be

inspected regularly for cracks and chips. If they

are damaged, they should be replaced as they

could damage your blades and bad guides

will detract from the performance of the

bandsaw. The guides should be cleaned

regularly and any wood gum or dirt removed.

Any commercially available solvent can be

used, and after cleaning they should be

lubricated with Teflon-based lubricant.

Drive Belt

The drive belt should last for many years

(depending on the usage) but needs to be

inspected regularly for cracks, cuts and general

wear. If damage is found, replace the belt.

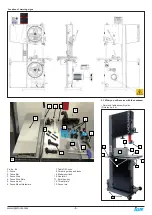

Replacing the drive belt

To replace the belts you will have to remove the

lower flywheel.

1. Loosen the motor clamp bolts and move the

motor so that the tension is completely

removed from the drive belt. Remove the blade.

Loosen the two hex nuts that hold the brake

to the bandsaw frame and slide it out of the way

of the disc.

2. Remove the flywheel shaft nut that clamps

the wheel axle (back of the bandsaw).

3. Pull the lower flywheel off the bandsaw. You

may have to use a gear puller to remove the

lower wheel.

4. Replace the drive belt.

5. Refit the lower wheel and re-clamp with the

flywheel shaft nut.

6. Tension the drive belt and tighten the motor

clamping bolts.

Note.

It is better to replace the drive belt early

than to have a breakdown during an

important job.

Note.

Take great care not to damage the

bearings when taking the flywheel off and

reassembling.

Table Insert.

The table insert (throat plate) is made of

aluminium and is designed to reduce damage

to the blade should they come in contact. If

the blade slot becomes too wide or the insert

becomes damaged by the blade, it should be

replaced. The replacement insert will have to

be fitted to the table hole. The insert is provided

with four jacking screws that can be adjusted so

that the insert is level with the top of the table.

Bearings

All bearings are sealed for life and do not

require any maintenance. If a bearing becomes

faulty, replace it.

Rust

The bandsaw is made from steel and cast

iron. All non-painted surfaces will rust if not

protected. It is recommended that the table be

protected by coating with wax if the machine is

not in constant use. All moving non-painted

surfaces (guides, rack and pinion, etc.) should

be lubricated/protected with a Teflon-based

lubricant.

Blade guide rack and pinion

The top guide when moved vertically tracks the

blade and comes factory-set. Adjustment

is provided should that mechanism become

misaligned. This is a tricky operation and

should only be attempted if an extreme error

has occurred.

Back guide forward/back adjustment.

1.

Four clamping bolts and two Allen jacking

screws are provided.

2.

Slightly loosen the two clamping bolts A and

tighten the bottom Allen screw B will bring the

guide forward.

3.

Slightly loosen the two clamping bolts C and

tighten the top Allen screw D will bring the guide

back.

4.

Make only very small adjustments. Tighten

the clamping bolts prior to checking the guide

vertical movement.

Note

: The machine comes factory-set, and no

adjustment should be required.

Adjusting the break

Back break adjustor

Front break adjustor

Flywheel not shown for clarity

The back break adjustor moves clockwise to

remove slack in the break pad.

The front break adjustor is rotated clockwise

with an allen key to remove slack in the break

pad.

Clamp bolts C

Allen jacking

screw D

Jack bolt B

Clamping bolts A

Rear Adjusting Knob

Front

Adjusting

Screw

Throat plate jacking screws

Tire brush

Drive belt

Motor drive pulley

Drive belt adjusting bolt

Flywheel shaft nut