MSD Legend Series Operation & Maintenance Manual | 29

Guide Blade Gap

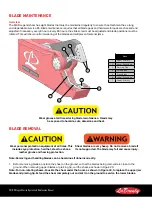

Figure 23

SHiM

gAP TO Be LeSS THAN

.030” (.762 MM)

Secondary Blades

The upper and lower jaw secondary blades must be parallel with each other and have less than .030 inch (.762 mm) gap.

Check the secondary blades gap every 8 hours of operation and each day, before using the attachment.

Note: For most applications a gap of .010 - .020 inches (.254 - .508 mm) will yield the best results. if jamming is a

problem with your specific material, the gap may be shimmed to .005 (.127 mm) inches.

Shear blades are very heavy. Do not remove a blade if

its not supported. The blade may fall and cause injury.

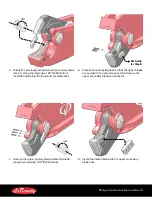

1.

Cycle the shear jaw until the upper and lower secondary blades overlap.

2.

Measure the gap in multiple places using a feeler gauge. The gap should be less than .030 (.762) inches.

Note: For most applications a gap of .010 - .020 inches (.254 - .508 mm) will yield the best results. if jamming is a

problem with your specific material, the gap may be shimmed to .005 (.127 mm) inches.

3. If the gap is larger than specified, you will need to shim the lower secondary blade.

4.

Loosen the three bolts that hold the lower secondary blade in the blade seat.

5.

Slide the blade so you can access the adjustment plate.

6.

Add shims between the blade and adjustment plate until the gap is as specified in the blade gap table (Page 30).

Note: When reinstalling the adjustment plates, ensure the notch is towards the shear.

gAP TO Be LeSS

THAN .030” (.762 MM)

Secondary Blade Gap

Figure 24

Shimming the Lower Secondary Blade

Figure 25

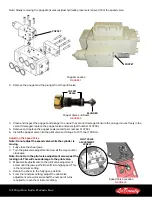

Primary Blades