26 | MSD Legend Series Operation & Maintenance Manual

BLADE MAINTENANCE

Overview

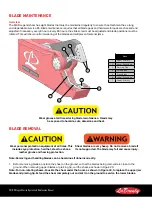

The MSD Legend shear has eight blades that must be maintained regularly to ensure the attachment has a long

and dependable service life. Blade maintenance requires that all blade gaps and hardware torques are checked and

adjusted if necessary every 8 hours. Every 80 hours, the slide screw must be adjusted and blade positions must be

rotated. This will ensure uniform wearing of the blades and will prevent material jams.

1

2

3

4

6

7

Blade

1

Upper Primary

2

Upper Secondary

3

Piercing Tips

4

Guide Blade

5

Cross Blade

6

Lower Secondary

7

Lower Primary

5

Wear gloves at all times during blade maintenance. Hands may

be exposed to hazards, cuts, abrasions and heat.

BLADE REMOVAL

Wear personal protection equipment at all times. This

includes eye protection, hard hat, steel toe shoes,

leather gloves and hearing protection.

Shear blades are very heavy. Do not remove a blade if

its not supported. The blade may fall and cause injury.

Note: removing and handling blades can be hazardous if done incorrectly.

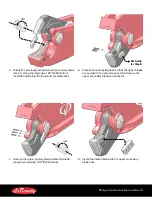

1.

Before removing blades, position the shear on the ground, so that the blades being removed are close to the

ground. When removing upper blades or piercing tip, curl the shear, as shown in Figure 20.

Note: For non-rotating shears, knuckle the shear under the boom, as shown in Figure 20, to replace the upper jaw

blades and piecing tip. extend the shear completely out and set it on the ground to service the lower blades.