18 | MSD Legend Series Operation & Maintenance Manual

•

When processing oversized material, make partial bites to start the breakage and then back off before making the

next partial bite. This will allow the broken material to fall away between bites.

•

When processing any rigid member, use the rotator to square the jaws to the cut. If the jaws are not square, the

rotator will back-drive to adjust to the cut.

•

When shearing large steel members, such as I-beams or tubing, try doing it in two cuts rather than one. Pierce the

material about halfway through with the first cut, and then finish it off with the second cut.

•

The shear jaws are best capable of processing light, thinner gauge materials immediately after performing

blade maintenance. When processing larger materials, the condition of the blades are not as critical. See “Blade

•

Sort your scrap to get the highest capacity from the attachment.

•

Start processing smaller materials and work up to larger materials. This will help you learn the limitations of the

machine and will allow the machine to warm up properly.

•

Understand that the attachment does have limits. Sometimes it may be necessary to downsize very large material

by another method before the attachment can process it effectively.

•

Cut material deliberately. Do not plunge the jaws into a pile of material and cut indiscriminately.

•

Keep the attachment properly maintained. Jaws with excessive blade gaps or dull teeth are much less effective.

Lack of maintenance can lead to greater problems and potential downtime.

•

Only use the force of the cylinder to cut material. Do not attempt to apply other forces on the shear to aid in material

processing.

•

The rotation function is for positioning only. Do not use it for bending, breaking or prying.

BLEED THE SHEAR HYDRAULIC CIRCUIT

Air must be bled out of the hydraulic circuit prior to operation. Air in the system leads to cavitation, oxidation of the

oil and excessive heat. These conditions promote hydraulic oil break-down, contamination, noise, sluggish operation,

reduced component life and potential cylinder damage.

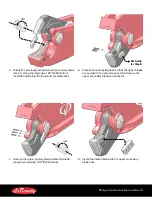

1.

Start with the shear in the vertical position.

2.

Set the excavator at idle speed.

3. Slowly open the jaws until a noticeable change in tone of the excavator is heard, indicating a full cylinder. Release

the controls and do not continue to apply full operating pressure to the cylinder.

4.

Slowly close the jaws until the cylinder rod is extended approximately 1/4 stroke.

5.

Open the jaws to retract the cylinder all the way.

6.

Repeat steps 3 and 4. Extend the cylinder a quarter stroke more each time, until you reach full stroke.

7.

Slowly cycle back and forth, at least five times, to full stroke. Be careful not to apply full operating pressure to the

cylinder at this time.

8. Check the base machine hydraulic fluid level and fill if necessary.

9.

Slowly extend and retract the excavator cylinder to it’s limits. Check for interference between the attachment and

the excavator boom or stick. Check the hydraulic lines that connect to the attachment. Ensure they are not rubbing

or becoming damaged in any way. Contact your dealer immediately if interference occurs.