LAARS Heating Systems

Page 62

12. close the make-up water valve. check the

strainer in the pressure reducing valve for

sediment or debris from the make-up water

line. Reopen the make-up water valve.

13. check the gauge for correct water pressure, and

also check the water level in the system. if the

height indicated above the boiler ensures that

water is at the highest point in the circulating

loop, then the system is ready for operation.

14. Refer to local codes and the make-up water

valve manufacturer’s instructions as to whether

the make-up water valve should be left open or

closed.

15. After placing the unit in operation, the ignition

system safety shutoff device must be tested.

First, shut off the manual gas valve, and call the

unit for heat. The main gas terminals will be

energized, attempting to light, for five seconds,

and then will de-energize. The unit will go into

lockout after the required number of trial for

ignition periods.

Second, press the manual reset button on the

boiler control, or the user display, open the

manual gas valve and allow the unit to light.

while the unit is operating, close the manual

gas valve and ensure that power to the main gas

valve has been cut.

16. within three days of start-up, recheck all air

bleeders and the expansion tank as described in

Steps 4 and 8 above.

note -

The installer is responsible for identifying to

the owner/operator the location of all emergency

shutoff devices.

WarnInG

Do not use this appliance if any part has

been under water. Immediately call a qualified

service technician to inspect the appliance

and to replace any part of the control system

and any gas control that may have been

under water.

Section 10

InItIal StartUP InStrUCtIonS

10.1 filling the Boiler System

1. Ensure the system is fully connected. close all

bleeding devices and open the make-up water

valve. Allow the system to fill slowly.

2. if a make-up water pump is employed, adjust

the pressure switch on pumping system to

provide a minimum of 12 psi (81.8 kPa) at the

highest point in the heating loop.

3. if a water pressure regulator is provided on

the make-up water line, adjust the pressure

regulator to provide at least 12 psi (81.8 kPa) at

the highest point in the heating loop.

4. Open any bleeding devices on all radiation

units at the high points in the piping throughout

the system, unless automatic air bleeders are

provided at those points.

note

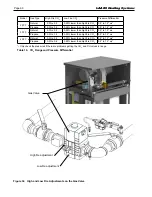

- There are three air bleeds located on top of

the water manifold.

WarnInG

Failure to remove all air from the heat

exchanger could lead to property damage,

severe injury or death.

6. Open all strainers in the circulating system,

check the operation of the flow switch (if

equipped), and check for debris. if debris is

present, clean out the strainers to ensure proper

circulation.

7. Recheck all air bleeders as described in Step 4.

8. check the liquid level in the expansion tank.

with the system full of water and under normal

operating pressure, the level of water in the

expansion tank should not exceed ¼ of the

total, with the balance filled with air.

9. Start up the boiler following the procedure

in this manual. Operate the entire system,

including the pump, boiler, and radiation units

for one hour.

10. Recheck the water level in the expansion tank.

if the water level exceeds ¼ of the volume of

the expansion tank, open the tank drain, and

drain to that level.

11. Shut down the entire system and vent all

radiation units and high points in the system

piping, as described in Step 4.