CAUTION

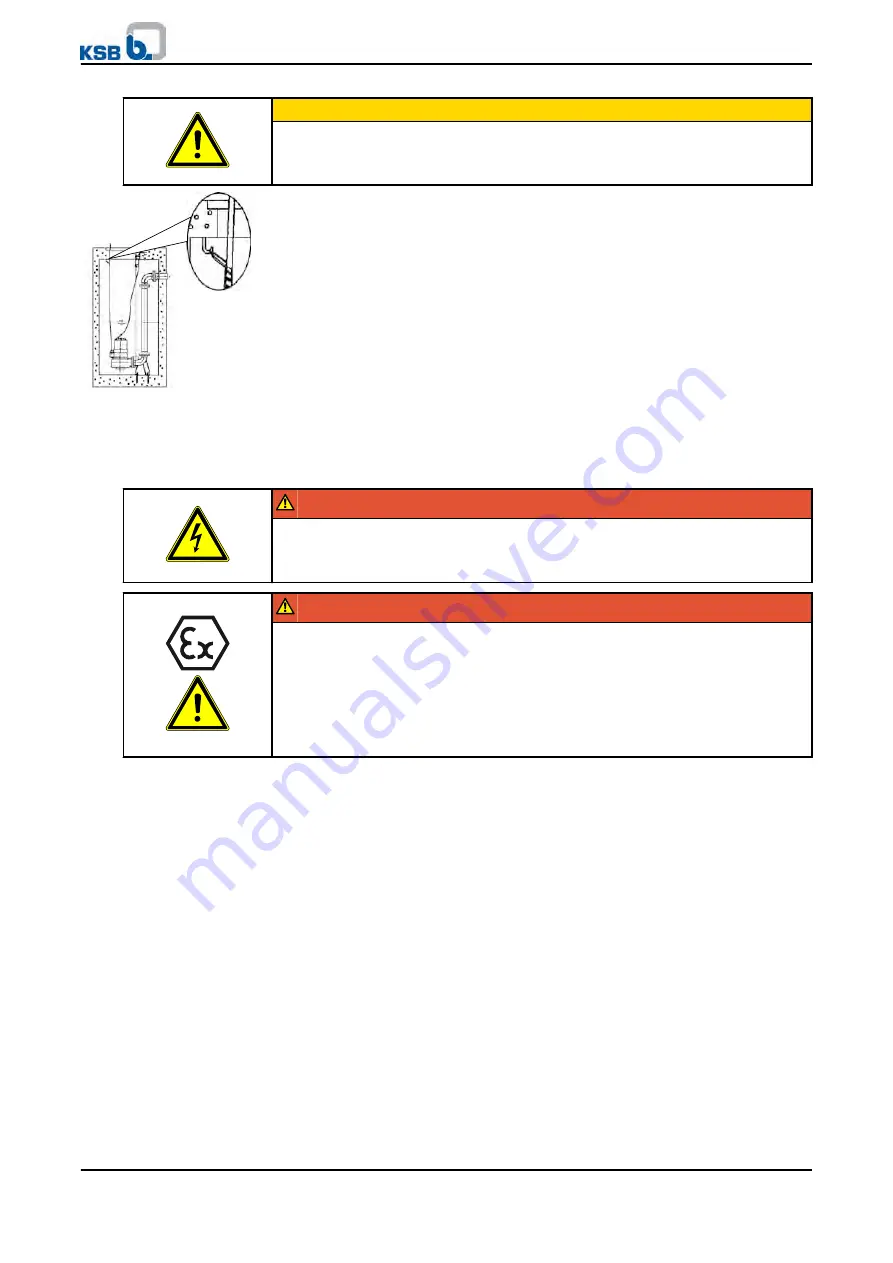

Flow-induced motion

Damage to the power cable!

▷

Run the power cable upwards without slack.

1. Run the power cables upwards without slack and fasten them.

2. Only remove the protective caps from the power cables immediately before

connecting the cables.

3. If necessary, adjust the length of the power cables to the site requirements.

4. After shortening the cables, correctly transfer the markings of the individual

cores at the cable ends.

Potential equalisation shall be provided for in compliance with EN 60 204. At variants

YL and WL the pump casing is designed with an inner thread for a M8 x 20 socket

head cap screw.

DANGER

Touching the pump set during operation

Electric shock!

▷

Make sure that the pump set cannot be touched during operation.

DANGER

Chemically corrosive fluids

Electric shock!

▷

If the pump set is used in chemically corrosive fluids, never use the external

terminal for potential equalisation.

▷

Connect the potential equalisation conductor to a non-wetted flange of the

discharge line and establish an electric connection between the newly fitted

potential equalisation and the pump set.

Fig. 18: Fastening the

power cables

Potential equalisation

conductor

5 Installation at Site

Amarex® N

31 of 66

Goodnal STP ST041 Biological Treatment (KSB WAS PUMP 1 & 2 PU-0530-010 OM Instructions) Vendor Manual

Q-Pulse Id VM381

Active 29/10/2013

Page 33 of 76