VI - 4

Maintenance

6.5

Adjusting the sensors

The bearing must be able to move. It must

therefore be regularly greased with a grease

gun, at least every 50 operating hours.

KDW06280

50h

Movement of the frame

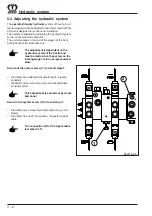

Delay in switching off the sensor is regulated by a tension

spring (1).

•

Increased tension on spring (1) = longer delay in

switching off = more force on metering rollers

•

Reduced tension on spring (1) = shorter delay in

switching off = less force on metering rollers

KDW06320

1

2

4

3

6.5.2 Switching off the scraper floor

The right bearing of the lower metering roller is a moving

part.

The motion sensor is on the underside of the bearing. It

registers movement of the metering roller.

6.5.1 Motion sensor for metering roller drive

The motion sensor is on the left side on the upper mete-

ring roller drive. It registers motion of the sprocket wheel.

The distance between the sensor and sprocket wheel

a =

2 mm

.

a

KDW06340

Summary of Contents for 4XL-RGD

Page 4: ...Foreword ...

Page 10: ...I 4 General information ...

Page 15: ...II 5 Safety ...

Page 22: ...II 12 Safety ...

Page 64: ...VI 18 Maintenance ...

Page 66: ...VII 2 Overwintering ...

Page 68: ...VIII 2 Recommissioning ...

Page 70: ...IX 2 Faults causes and removal ...

Page 80: ...A 10 Appendix Operator friendlyoperation A2 Electrical circuit diagram ...

Page 81: ...A 11 Appendix ...

Page 82: ...A 12 Appendix ...

Page 83: ...A 13 Appendix ...