BREAK-IN INSPECTIONS

HRS

ITEM

CHECK

Every

0.25

Road

or 1

Field

Drive Wheel Nuts

Torque: 220 ft∙lbf (300 N∙m).

Repeat checks until torque stabilizes.

5

A/C Belt

Tension.

Caster Wheel Nuts

Torque: 120 ft∙lbf (163 N∙m).

Caster Wheel Anti-Shimmy

Dampener Bolts

Inboard Bolt Torque: 100 ft∙lbf (135 N∙m).

Outboard Bolt Torque: 85 ft∙lbf (115 N∙m).

Walking Beam Width

Adjustment Bolts

Torque: 330 ft∙lbf (448 N∙m).

10

Walking Beam Width

Adjustment Bolts

Torque: 330 ft∙lbf (448 N∙m).

Drive Wheel Nuts

Torque: 220 ft∙lbf (300 N∙m).

Repeat Checks until torque stabilizes, and

at 20 and 30 hours.

Neutral

Dealer Adjust.

50

Hose Clamps: Air Intake,

Radiator, Heater, Hydraulic Hand-tighten unless otherwise noted.

Walking Beam Bolts

Torque: 330 ft-lbf (448 Nm).

Caster Wheel Anti-

Shimmy Dampener Bolts

Torque Inboard: 100 ft-lbf (135 Nm).

Torque Outboard: 85 ft-lbf (115 Nm).

Drive Wheel Nuts

Torque: 220 ft-lbf (300 Nm).

Repeat check until torque stabilizes.

Engine Gearbox Oil

Change.

Drive Wheel Oil Lubricant

Charge System& Hydraulic

Oil Filters (except lift)

Manifold Oil Pressure

ONGOING MAINTENANCE INTERVALS

TIME

SERVICE

10 Hours or

Daily

1. Check Tire Inflation.

2. Check Engine Oil Level.

3. Check Engine Coolant Level At Reserve Tank.

4. Clean Radiator, Hydraulic Oil Cooler, Charge Air Cooler,

and A/C Condenser.

5. Check Hydraulic Oil Level.

6. Drain Fuel Filter Water Trap.

7. Fill Fuel Tank.

8. Check Hydraulic Hoses and Lines For Leaks.

50 Hours

1. Grease Caster Pivots.

2. Grease Walking Beam Center and Top Lift Link Pivots.

3. Grease Forked Caster Spindle Bearings.

4. Clean Cab Fresh Air Intake Filter.

5. Check Gear Box Oil Level.

100 Hours or

Annually

1. Clean Cab Air Return Filter.

NOTE: Refer to M155 Operator’s Manual for

250, 500, 1000, 1500, 2000, 5000 Hour and Annual Maintenance.

FLUIDS AND LUBRICANTS

FLUID

VOL

SPEC

DESCRIPTION /

INFORMATION

Fuel:

Diesel

No.2

97 US

Gallons

(367 L)

ASTM

D-975

Grade S15

Sulphur (by weight)

0.5% max.

Water and Sediment

(by vol) 0.05% max.

Lubricity 520 HFRR

Fuel:

Diesel

No.1 and

No. 2 Mix

97 US

Gallons

(367 L)

n/a

Sulphur (by weight)

0.5% pref. 1% max.

Water and Sediment

(by weight) 0.1% max.

Lubricity 460 HFRR

Coolant

6.6 US

Gallons

(25 L)

ASTM

D-4985

Ethylene Glycol

with SCA,

mixed equally with

high quality

deionized, distilled,

demineralized water

Rated to -30

F (-34

C)

Grease

N/A

SAE Multi-

Purpose

High Temperature

Extreme Pressure EP2.

Max 1% molybdenum

disulphide, Lithium

base. Use as required

unless otherwise noted

Engine

Oil

13.7 US

Quarts

(13 L)

SAE 15W40

for API Class

SJ and CH-4

Engine Crankcase

Hydraulic

Oil

17.2 US

Gallons

(65 L)

SAE 15W40

for API Class

SJ and CH-4

Windrower Drive and

Header Drive

Gear Box

Lube

2.2 US

Quarts

(2.1 L)

SAE 75W-90

API Service

Class GL-5.

E Synthetic

Trans Lube

Engine Gearbox

A/C

Refriger-

ant

3.6 lb

(1.63 kg)

R134A

Cab A/C System

A/C Com-

pressor

Oil

8.1 fl. oz

(240 cc)

SP-15

PAG

Cab A/C Compressor

Lubricant

TIRE PRESSURES

Drive

Tires

18 - 26 BAR

32 psi (221 kPa)

600 - 65 R28 BAR

26 psi (179 kPa)

580 / 70 R26

TURF

24 psi

(165 kPa)

18.4 - 26 TURF

35 psi (241 kPa)

23.1 - 26 TURF

20 psi (138 kPa)

Rear

Tires

All Rear Tire Pressures are 10 psi (69 kPa)

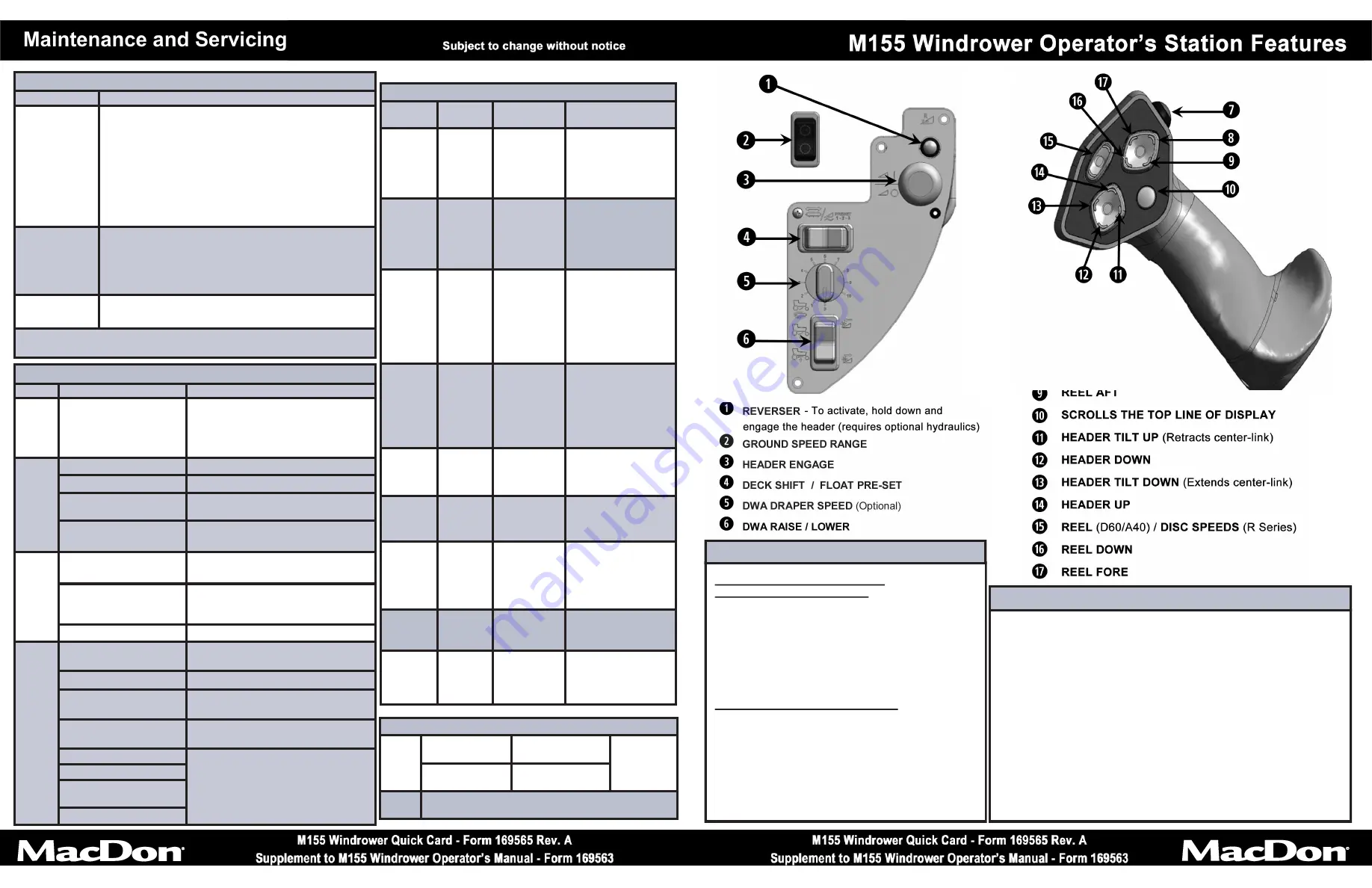

A-Series, R-Series, or D-Series -

Without Hydraulic Deck Shift

FLOAT PRE-SET / DECK SHIFT switch allows for

auto-memory of three different trim cylinder

positions. For example:

#1 - Border Width LH 5.0, RH 6.5

#2 - Normal Width LH 5.0, RH 5.0

#3 - Rocky Width LH 6.5, RH 6.5

D-Series with Hydraulic Deck Shift

DECK SHIFT switch activates hydraulic deck shifting

when the header is engaged, and allows for auto-

memory of trim cylinder adjustments in each delivery

opening position.

Allows for compensation of weight shifts to the float

springs.

FLOAT PRESETS

1. Main battery disconnect switch - POWER

ON

.

2. GSL in

N-DETENT.

HEADER DRIVE switch

OFF.

3. Seat Belt

ON

. Set throttle to

START

position - “fully back”.

4. Sound horn three times.

5. Turn ignition key to

RUN

position. Single loud tone sounds.

Engine warning lights flash in self-test mode, and CDM displays

“HEADER DISENGAGED’ and “IN PARK”.

6. Turn ignition key to

START

position until engine starts.

Release key. Allow engine to run at IDLE until temperature reach-

es 100

F (40

C).

7. CDM displays programmed header data for 5 seconds, and then

returns to previous display.

NORMAL START - Engine Temp above 60°F (16°C)