Precautions for maintenance

SAFETY

Safety instructions

2-34

Handling high-pressure hoses

0.

If oil or fuel leaks from high-pressure hoses, it may cause fire or defective operation, which may lead to serious

injury or property damage. If any loose bolts are found, stop work and tighten to the specified torque.

If any damaged hoses are found, stop operations immediately and contact your Komatsu distributor.

Replace all hoses every six years at the latest. The shelf life of the hose should not exceed 2 years.

Hoses must be replaced as soon as the following damage is noticeable:

damage to the outer layer through to the intermediate layer,

brittleness in the outer layer,

distortions in pressurised or unpressurised state not conforming with the original shape of the installed hose,

leakages,

damage to the hose fittings or to the connection between fittings and hose,

storage damage.

When replacing the hoses, always replace the O-rings, gaskets, and other such parts at the same time.

See also "Periodic replacement of safety critical parts on page 4-15".

Waste materials

0.

To prevent pollution, pay careful attention to the method of disposing of waste materials.

Always put oil drained from your machine in containers.

Never drain oil directly onto the ground or dump into the

sewage system, rivers, the sea, or lakes.

Obey appropriate laws and regulations when disposing of

harmful objects such as oil, fuel, coolant, solvent, filters, and

batteries.

Maintenance of air conditioner

0.

If air conditioner refrigerant gets into your eyes, it may cause blindness; if it touches your skin, it may cause

frostbite.

Never touch refrigerant.

Compressed air

0.

When carrying out cleaning with compressed air, there is a hazard of serious injury caused by flying particles.

When using compressed air to clean elements or the radiator, always wear safety goggles, dust mask, gloves,

and other protective equipment.

Periodic replacement of safety critical parts

0.

In order for the machine to be operated safely for a long time, it is necessary to add oil and to carry out service

and maintenance at periodic intervals. In order to further increase safety, components with a strong relation-

ship to safety, such as hoses and seat belts, must be replaced at periodic intervals.

Replacement of safety critical parts: see "Periodic replacement of safety critical parts on page 4-15".

The material of these components naturally changes over time, and repeated use causes deterioration, wear,

and fatigue. As a result, there is a hazard that these components may fail and cause serious injury or death. It

is difficult to judge the remaining life of these components from external inspection or the feeling when operat-

ing, so always replace them at the specified interval.

Replace or repair safety-critical parts if any defect is found, even when they have not reached the time speci-

fied interval.

Replace all hoses every six years at the latest. The shelf life of the hose should not exceed 2 years.

Summary of Contents for WA250PT-5H

Page 2: ......

Page 3: ...FOREWORD 11...

Page 16: ...Contents FOREWORD 1 14...

Page 24: ...SAFETY 2 2...

Page 58: ...Precautions with tires SAFETY Precautions when storing tires 2 36...

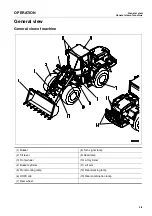

Page 60: ...OPERATION 3 2...

Page 233: ...TECHNICAL DATA 45...

Page 235: ...TECHNICAL DATA Technical data 5 3...

Page 250: ...Central lubrication system ATTACHMENTS OPTIONS 6 14...

Page 251: ...INDEX 67...

Page 252: ...INDEX 7 2...

Page 255: ...Index 7 5...