MAINTENANCE

Service procedure

Every 250 hours service

4-43

Check parking brake

0.

Test conditions

Tire inflation pressure: as specified

Road surface: Dry paved surface with 25% grade

Machine: Operating condition

Test method

1. Start the engine and set the work equipment to the travel

posture.

2. Align the machine facing straight to the front, then drive the

machine up a 25% grade with the bucket empty.

3. Apply the brake to stop the machine, return the directional

lever to the neutral position ‚N', set the parking brake to the

LOCK position and stop the engine.

4. Release the brake pedal slowly and check whether the

machine is held in Stop position.

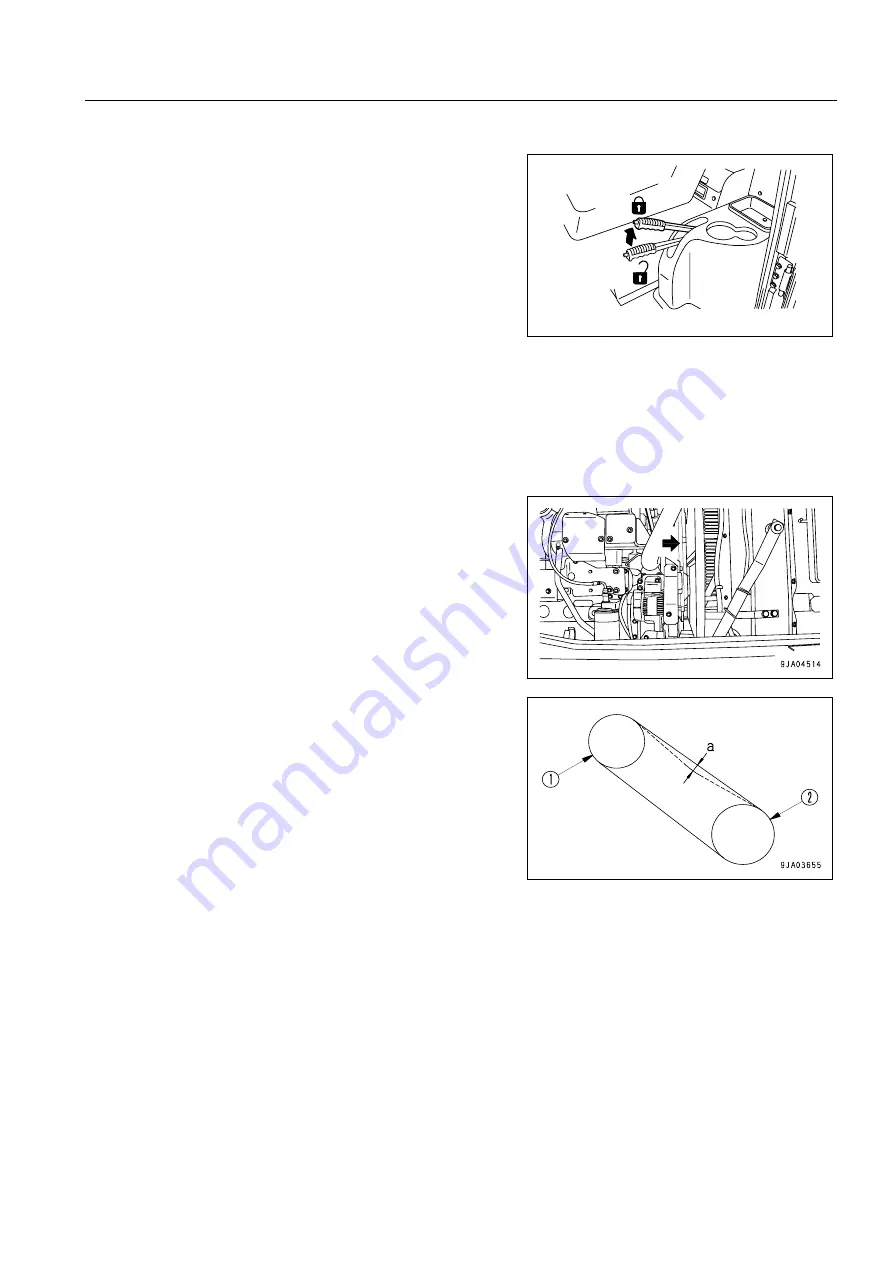

Check air conditioner compressor belt tension, adjust

0.

Checking

0.

1. Open the engine side cover on the left side of the chassis.

2. Standard deflection “a“ between air conditioner compressor

pulley (1) and fan pulley (2) when pressed with a thumb

(approx. 98 N (10 kg)) should be approx. 9.5 to 13.5 mm

(0.4 to 0.5 in).

When a belt tension gauge is used, the standard tension is

within a range of 353 to 549 N (36 to 54 kgf).

Check when changing the V-belt

0.

The standard deflection between the air conditioner compressor pulley and fan pulley when pressed with a thumb

(approx. 98 N (10 kgf)) should be approx. 7 to 10 mm (0.28 to 0.4 in).

When a belt tension gauge is used, the standard tension is within a range of 533 to 745 N (54 to 76 kgf).

REMARK

When the belt has been replaced with a new part, a high tension is necessary, so the initial tension is in

the value given above.

9EA04476-A

Free

Lock

Summary of Contents for WA250PT-5H

Page 2: ......

Page 3: ...FOREWORD 11...

Page 16: ...Contents FOREWORD 1 14...

Page 24: ...SAFETY 2 2...

Page 58: ...Precautions with tires SAFETY Precautions when storing tires 2 36...

Page 60: ...OPERATION 3 2...

Page 233: ...TECHNICAL DATA 45...

Page 235: ...TECHNICAL DATA Technical data 5 3...

Page 250: ...Central lubrication system ATTACHMENTS OPTIONS 6 14...

Page 251: ...INDEX 67...

Page 252: ...INDEX 7 2...

Page 255: ...Index 7 5...