3 - 5

Chapter 3. Troubleshooting

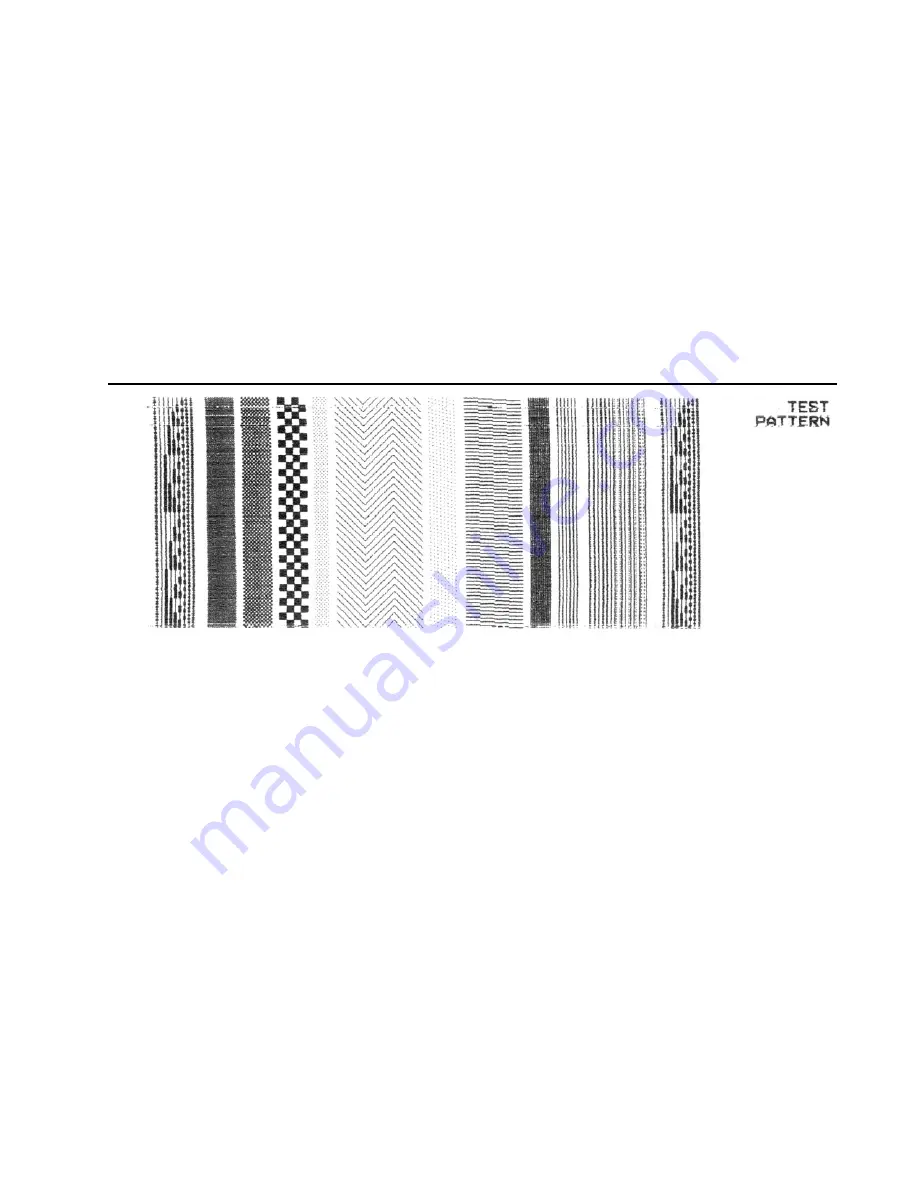

Identifying Print Defects

Ragged Print

General raggedness is most common problem encountered with 7122

printheads. Raggedness falls into the following three categories:

•

Slight - caused by dried ink buildup during normal operation

•

Serious - caused by contamination or lack of cleaning

•

Startup - caused by dried ink buildup on a shut down system.

Slight Raggedness

Dried ink buildup on eyelid seal or catcher edge

will cause slightly ragged print. The normal clean cycle should prevent it

(see “Standby Pan Installation” in Chapter 4, “Maintenance”). Persistent

raggedness may require swabbing. Figure 3.3 shows mild raggedness on

the upper portion of a test pattern run at 130 volts and 41 phase counts on

a printhead with 150 hours.

Figure 3.3

Slight raggedness, sample test pattern

Mild raggedness

Summary of Contents for VERSAMARK DP7122

Page 1: ...Kodak Versamark Inc KODAK VERSAMARK DP7122Printer Operator s Guide ...

Page 2: ......

Page 3: ...KODAK VERSAMARK DP7122 Printer Operator s Guide Block 3 Mod 11 ...

Page 8: ......

Page 24: ......

Page 37: ...3 7 Chapter 3 Troubleshooting Identifying Print Defects Figure 3 4 continued ...

Page 44: ......

Page 56: ......

Page 61: ......