Page 39

Copyright © 2012 Kato Engineering, Inc. All rights reserved

IMPORTANT: The following procedures are

meant to be a general guide. Procedures for

your unit may vary.

WARNING: Ensure the generator

has stopped and is de-energized before

disassembly. A rotating generator is always

producing some voltage and contact with

the leads or other devices connected may

result in serious injury or death

WARNING: Use a hoist and slings

or chains to support components during

removal. Use lifting devices that are

selected for generator component weights.

Improper lifting techniques may cause

serious injury or death. Be extremely

careful not to damage components.

NOTICE: Ensure the generator fi eld wires

are fl at in the wireway so they don’t tear

during pulling. Do not pull on the edges of

the heat sinks or on the exciter armature

windings.

NOTICE: Make sure the pipe is strong

enough to support the weight of the rotor

and that it does not have rough edges on

the inside, which could damage the shaft.

NOTICE: To prevent tension on the shaft,

put the slings around the largest shaft step

possible.

NOTICE: Make sure the rotor does not

rest on the stator during the stages of

movement. Make sure the rotor does not hit

the stator.

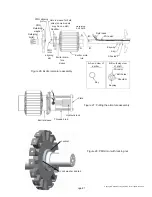

Disassembly

Overall disassembly

1. Remove the terminal box cover, and disconnect the load leads and

all other leads. Tag the leads to ensure they are correctly connected

when the generator is reassembled.

2. Remove the bolts securing the generator to the base and prime

mover, and move the generator to an area that allows suffi cient room

for disassembly.

3. Remove the coupling or drive plates.

4. Remove the exciter cover.

5. Remove the clips securing the exciter fi eld leads to the exciter frame

and endbracket. Disconnect the leads and remove the exciter frame/

stator and/or exciter-PMG frame/stator.

6. Remove the (optional) PMG and exciter armature as described

below.

7. Support the shaft. Remove the exciter-end endbracket bolts, and

remove the endbracket. Tap lightly with a rubber or fi ber mallet

to loosen the endbracket if necessary. Repeat with the drive-end

endbracket (if applicable).

8. Remove the fan from the hub where applicable. If necessary, make

sure to mark the location of the fan for reinstallation.

9. Float out the rotor (see Figure 25). First attach a pipe over the shaft

on the drive end. Attach slings around the pipe on one end and

around the shaft on the opposite end. Lift up the rotor, and move it

out, resting the rotor as the slings are moved down the pipe for the

next lifting stage.