Page 36

Copyright © 2012 Kato Engineering, Inc. All rights reserved

Dry out procedures

If the insulation resistance readings are below the recommended mini-

mum values specifi ed previously, use one of the dry out procedures

described below. Select the procedure based on the size and location

of the unit, available equipment, and experience of personnel. Before

drying, remove the voltage regulator, and cover all inlet and discharge

openings. Provide an opening at the top of the machine, preferably at the

fan end, for moisture to evaporate.

Drying with external heat: Place heat lamps, space heaters (in addition

to the ones already supplied) or a steam pipe near the windings. Monitor

winding temperatures. Raise winding temperature gradual ly at a rate

of 10-20° F (-12° to -6°

C) per hour up to 200° F (93° C). Measure

insulation resistance at 1-hour intervals. Typically the insulation

resistance will slowly drop while the temperature is coming up, and then

gradual ly increase and level out.

Drying with AC current in the armature: Short circuit the generator

terminals. Provide DC excitation to the brushless exciter fi eld winding.

Insert a current transformer and an ammeter to read full load current.

Run the generator at rated speed. Apply excitation to the exciter fi eld

until rated current is developed. Monitor winding temperatures until they

stabilize. Continue running until insulation resistance values level off.

Monitor winding temperatures. Raise winding temperature gradually at a

rate of 10-20° F (-12° to -6°

C) per hour up to 200° F (93° C). Measure

insulation resistance at 1-hour intervals. Typically, the insulation

resistance will slowly drop while the temperature is coming up and then

gradually increase and level out.

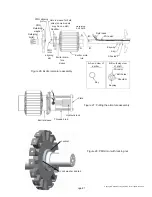

Bearing lubrication

Shielded or sealed ball bearings: Shielded or sealed ball bearings are

factory packed with lubricants and generally can be operated several

years without requiring replenishment or change of the grease. If

repacking the grease is necessary, disassemble the machine, clean the

bearings, and repack the bearings about 1/2 full using a high quality ball

bearing grease, which must be capable of lubricating satisfactorily over a

temperature range of the lowest ambient temperature to 250º F (121

o

C).

Regreaseable ball or roller bearings: In applications where regreaseable

bearings are used, grease fi ll fi ttings and relief valves are incorporated

into the bearing housing. Lubricate the bearings in accordance with the

lubricating instructions attached to the generator.

Sleeve bearings: Lubricate the bearings in accordance with the

lubricating instructions attached to the generator and the bearing

lubrication instructions, which are provided in the manual package as

supplementary material.

NOTICE: Do not apply heat too rapidly. It

could damage the windings.

NOTICE: For specifi c lubrication

instructions, always refer to the bearing

lubrication sheet that came with your manual

or the lube plate on the generator.