Maintenance

10 --- 66

Dispose of parts and materials contaminated with oil in accordance

with local environment protection regulations.

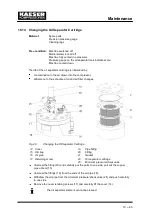

Take out the old oil separator element (23) together with the gaskets (21) and dispose

of according to environmental regulations.

Wipe all sealing faces with a cleaning rag.

Insert the new oil separator cartridge with gaskets and re---fix the cover.

Renew the dirt trap (15) strainer and O ---ring.

Connect the air pipe to the minimum pressure/check valve.

Replace and tighten all fittings.

Start the machine and carry out a test run

Close all access doors; replace and secure all removable panels.

Open the user’s shut ---off valve between the machine and the air main.

Switch on the power supply and reset the maintenance interval counter.

Allow the machine to idle for at least one minute. Then switch to LOAD.

Carry out a visual check for leaks.

Summary of Contents for CSD 82

Page 2: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

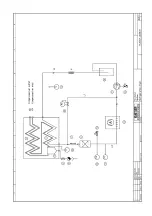

Page 91: ...Appendix 13 83 13 2 2 Pipeline and instrument flow diagram option C1...

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

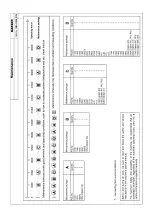

Page 97: ...Appendix 13 89 13 2 3 Dimensional drawing 13 2 3 1 Air cooling option K1...

Page 98: ......

Page 99: ......

Page 100: ...Appendix 13 92 13 2 3 2 Water cooling option K2...

Page 101: ......

Page 102: ......

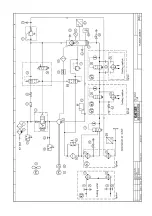

Page 103: ...Appendix 13 95 13 2 4 Electrical diagram...

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......