Installation

6 --- 26

Shut ---off valve (2) to be installed by the user in the connection line.

Make the compressed air connection with a flexible hose (1) or an axial compensa-

tor (1).

6.4

Electrical Connection

Have the electrical connection made only by a qualified and authorised electrician.

Carry out protection measures as stipulated in relevant regulations (IEC 364 or DIN

VDE 0100, for example) and in national accident prevention regulations (BGV A2 in Ger-

many). Also observe the regulations of the local power utility company.

Use wire conductor dimensions and fuse ratings in accordance with local regulations (DIN

VDE 0100 parts 430 and 523 in Germany, for example).

Check the reaction time of overload protection devices (e.g. DIN VDE 0100 part 413).

Guide values are given in chapter 2.8.

The user must provide the machine with a lockable supply ---disconnecting device.

This could be, for example, a switch ---disconnector with fuses. If a circuit breaker is

used it must be suitable for the motor starting characteristics.

Before initial start--- up

The control transformer in the control cabinet has connections for various supply volt-

ages. Check that the correct connections are made for the supply voltage provided for

the machine. If necessary, re---connect the transformer using the

5% taps to match

the supply voltage.

Connect the machine to the mains power supply in accordance with the electrical dia-

gram in chapter 13.2.4.

6.5

Options

6.5.1

Machine fixing (option H1)

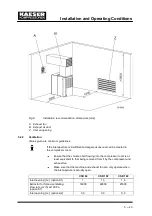

If the machine is supplied with mountings, these can be used to anchor it to the floor. De-

tails of the fixing holes are contained in the dimensional drawing in chapter 13.2.3.

Use appropriate bolts to anchor the machine.

6.5.2

Water cooling connection (option K2)

The dimensional drawing in chapter 13.2.3 gives the flow direction, size and position of the

cooling water connection ports.

Use connecting lines made of the appropriate material for the water system. Take into ac-

count the effect of electro ---chemical reaction.

Keep the effect of pressure surge on the cooler as low as possible.

Where pressure surges are unavoidable provide an expansion tank to damp pulsations.

Summary of Contents for CSD 82

Page 2: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ...Appendix 13 83 13 2 2 Pipeline and instrument flow diagram option C1...

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ...Appendix 13 89 13 2 3 Dimensional drawing 13 2 3 1 Air cooling option K1...

Page 98: ......

Page 99: ......

Page 100: ...Appendix 13 92 13 2 3 2 Water cooling option K2...

Page 101: ......

Page 102: ......

Page 103: ...Appendix 13 95 13 2 4 Electrical diagram...

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......