8 / 13

JUNG ANTRIEBSTECHNIK U. AUTOMATION GMBH

♦

Felsweg 18

♦

35435 Wettenberg

♦

Germany

Tel.: +49-(0)641-48017-0

♦

Fax: +49-(0)641-48017-15

♦

eMail: [email protected]

♦

www.ja2-gmbh.de

3.2

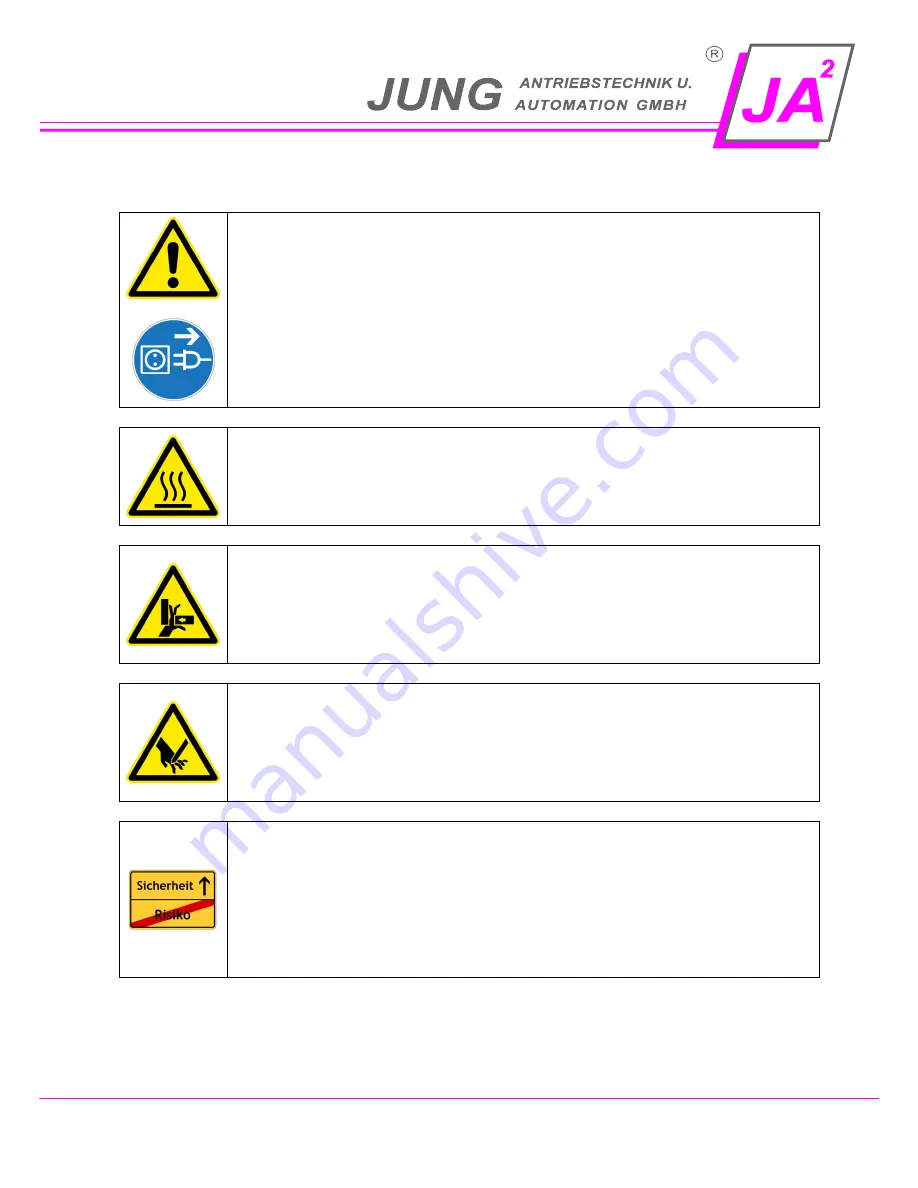

Warnings for Intended Use

Fast moving Machine Parts

Our linear motor systems are high-dynamic machine elements. Necessary

precautions must be taken to prevent contact with moving parts during

operations. This can be done by installing covers, enclosures, light curtains,

safety mats, etc..

Operations, without appropriate safety measures are forbidden. Operations

may only be carried out by qualified personnel. During assembly the

machine is to be turned off!

Burn Hazards

The sliders of linear motors can reach temperatures of 80 °C during

operations, which may cause burns upon contact.

Bruises & Sprains

Our linear motor systems can apply very high accelerations, high top speeds

and forces over 1.000 N. Depending on the application and the duration of

exposure apropriate protective devices must be used!

Severing of Limbs

Our linear motor systems can apply very high accelerations, high top speeds

and forces over 1.000 N. Depending on the application and the duration of

exposure apropriate protective devices must be used!

Risk Assessment & Performance Level (PL) of Protective Measures

Since the risk depends on the type of machine, the assembly conditions and

the implemented protective measures, a general specification to minimize

risks during assembly cannot be given by us. We recommend the software

assistant SISTEMA for risk assessment and evaluation of the PL according

to DIN EN ISO 13849.