12

www.joule.ie

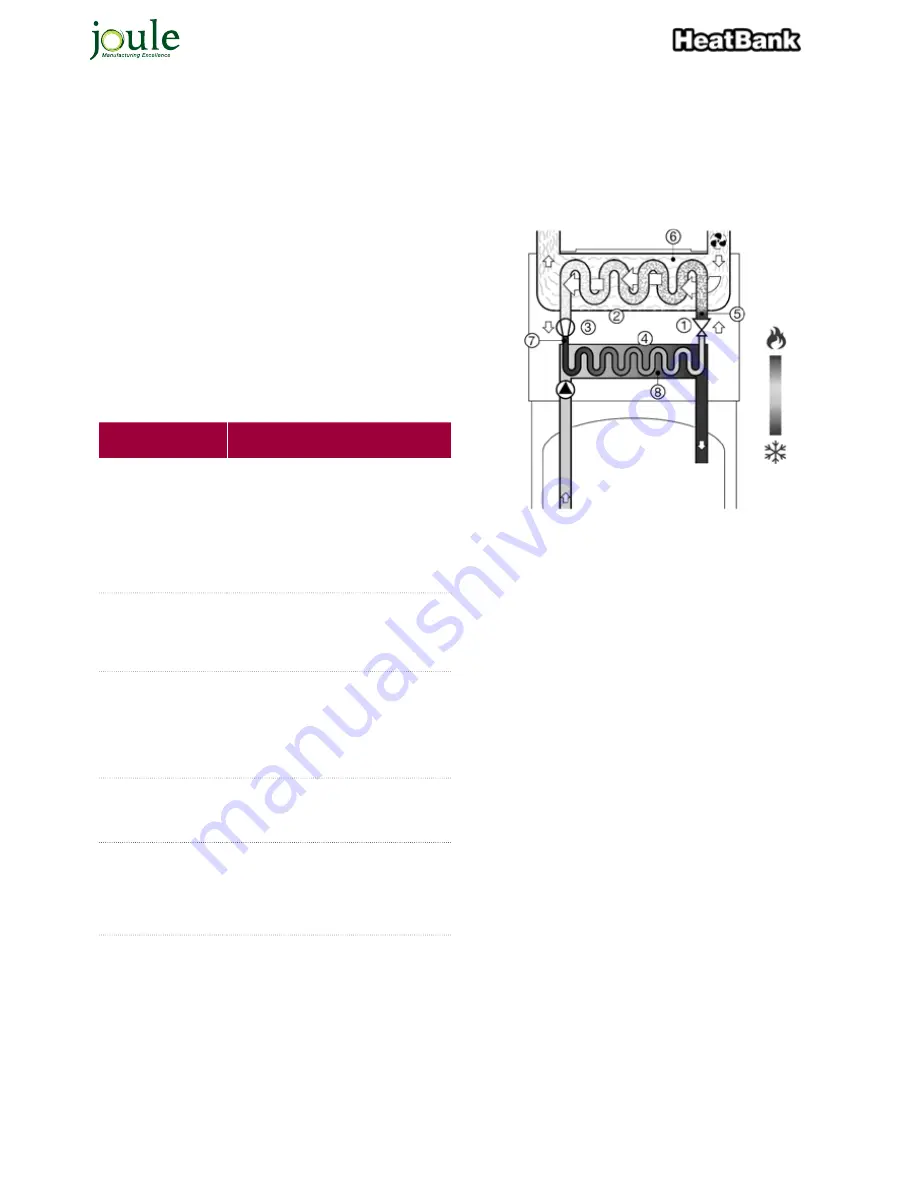

1.8 OPERATING PRINCIPLE OF THE VENTILATION

HEAT PUMP WATER HEATER

The Ventilation Heat Pump Water heater consists of an expansion

valve (1), an air heat exchanger (2), a compressor (3) and a water heat

exchanger (4).

A refrigerant circulates in the closed system (5). In the expansion valve,

the pressure and temperature of the refrigerant are lowered, which

becomes vaporous. It extracts heat from the air (6) via the air heat

exchanger . The vapour is then compressed

by the compressor . This increases the pressure and the temperature

(7). The heat is transferred to the water via the water heat exchanger

(8). And the cycle begins anew. It is therefore possible to heat water

with a low temperature of 10 °C to domestic hot water with a tem-

perature of 60 °C. This makes it possible to create four parts of energy

(heat) from just one part of energy (electricity).

10

ENG

Installation and user manual

1.7 OPERATING PRINCIPLE OF THE VENTILATION HEAT PUMP WATER HEATER

The Ventilation Heat Pump Water heater consists

of an expansion valve (1), an air heat exchanger (2),

a compressor (3) and a water heat exchanger (4).

A refrigerant circulates in the closed system (5). In

the expansion valve, the pressure and temperature

of the refrigerant are lowered, which becomes

vaporous. It extracts heat from the air (6) via the air

heat exchanger. The vapour is then compressed

by the compressor. This increases the pressure

and the temperature (7). The heat is transferred to

the water via the water heat exchanger (8). And the

cycle begins anew. It is therefore possible to heat

water with a low temperature of 10 ºC to domestic

hot water with a temperature of 60 ºC. This makes

it possible to create four parts of energy (heat) from

just one part of energy (electricity).

Configurations which

are not allowed

Consequences

Connection to the attic

or loft space .

When the insulation between the house and

the attic is not sufficient, through this con-

nection the loss of heat may increase . There

is also the possibility that a growing of mois-

ture will happen at the ceiling of the rooms

which are directly below the attic . There is

a chance that objects will fall or dust will be

drawn in by the VHW . This may reduce the

lifetime for the VHW .

The supply of air from

a heated room by the

VHW .

The air which is drawn by the VHW is al-

ready warmed by another heating source

in the system . In this situation the great-

est benefit of the VHW (the transmitting of

‘free’ energy into heat) is not used.

Connection to the me-

chanical ventilation .

he volume of air required by the VHW isn’t

suitable (380 / 490 m/h) for the volume of

air in a mechanical ventilation (which is

100 m/u). Furthermore the vapor of grease

and dust in the ducts of the mechanical

ventilation can circulate through and that

may cause a shorter lifetime for the VHW .

Making of a housing

around the air outside or

a repulsion of fresh air

inside .

This will cause a big loss in the coefficient

of performance and a strong cooling in the

room .

Connection to a ground

heat exchanger .

• Friction losses.

• Problems with the symmetrisation of

the two fans inside the ground heat ex-

changer .

• The evaporator will likely become

clogged .

Not allowed

• Make a ventilation connection with a dryer.

• Install in dusty room.

• Take air in which contains solvents and / or explosive substances.

• Connect the VHW to an extractor fan wich drains oily and contami-

nated air .

• Install the VHW in a room where there is a change of frost.

• Install the VHW on top of the boiler.

• Install in an atmosphere which is chlorinated (e.g. a swimming

pool) or fluorinated. • Install nearby sea areas or chemical plant

• Dusty air intake.