Fig 20

Install the curved guard body first.

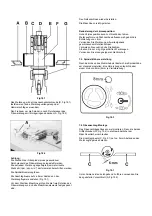

The machine table is therefore prepared with a M8 tapped

hole (A, Fig 21) and an 8mm pinhole (P).

Fig 21

Set the height of the guide plate (B, Fig 22) depending on the

position and diameter of the tool and the thickness of the

workpiece. This part guides the wood and must always be

above the cutter.

Fig 22

Use knob (E, Fig 23) to set the chip removal.

Fig 23

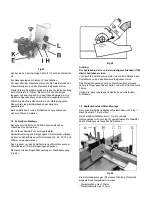

Slide the cover (C) down until it touches the part to be

machined.

Connect the dust collector to the curved guard port (K).

Before starting work, check manually that the cutter rotates

freely and that all components are correctly clamped.

At the start of the cut, move the workpiece along the straight

part of the guide plate (F). This way the workpiece enters the

cutter gradually, reaching the maximum depth of cut at the

guide plate mark.

Continue by moving the workpiece, keeping it aligned with the

guide plate mark.

When working complex shapes, make jigs and guides to guide

the workpiece properly and safely.

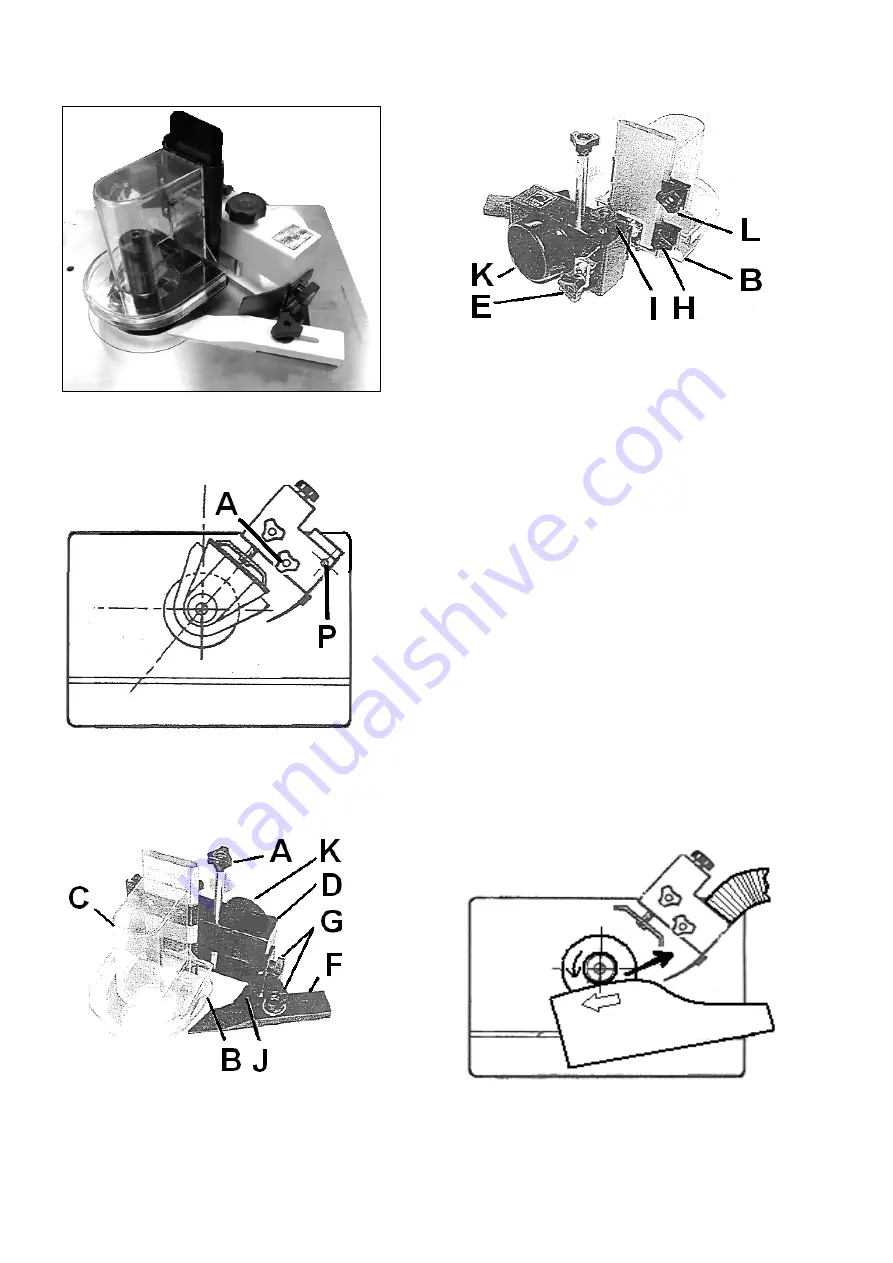

7.8 Sanding spindle installation

The optionaly available sanding spindle can be mounted in

place of the 30mm spindle arbour.

The sanding spindle may only be installed when the spindle

rotation lock is engaged and the mains plug is pulled.

Sanding sleeves and drums can be chosen between dia. 25,

38, 50, 75 and 100mm.

Cover the clearance zone around the sanding sleeve with

table insert rings.

Install the curved guard body for dust collection (Fig 24).

Fig 24

Summary of Contents for JWS-34KX

Page 44: ...A 1 A 2 A 3 A 4 A 5 ...