Fig 5

When working complex shapes, make jigs and guides to guide

the workpiece properly and safely.

Tenoning work requires the optionaly available tenoning

carriage (see chapter 7.9)

The fence must securely be locked before starting the

machine.

Make trial cuts on a piece of scrap before working the actual

workpiece.

Support long workpieces with helping roller stands or table

extensions.

Always work one workpiece at a time.

Never operate with the guards not in place – serious risk of

injury!

Always keep your hands well clear of the rotating tool.

Never machine a workpiece if it cannot be guided properly

and safely with sufficient distance to the cutting tool.

When working complex shapes, make jigs and guides to guide

the workpiece properly and safely.

Adapt the spindle speed to the cutting tool diameter.

For the authorized use of the machine observe the

appendix A

“safe operation“

(on the last pages of this operating manual)

A.1 : Machining of boards

A.2 : Longitudinal machining

A.3 : Face machining

A.4 : Recess machining.

A.5 : Contour machining

7. Setup and adjustments

General note:

Setup and adjustment work may only be carried out after

the machine is protected against accidental starting by

pulling the mains plug.

Make sure that the cutter is running clear after every setup or

adjustment done.

7.1 Spindle speed setting

Warning:

The spindle speed must be selected according to the

cutter diameter.

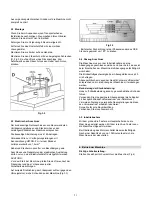

The cutting speed in m/sec corresponding to tool diameter

and spindle speed can be seen on the diagram (Fig 6).

The diagram also can be found on the machine.

Fig 6

At the lower spindle speeds and at smaller tool diameters an

increased risk of workpiece kickback exists.

The maximum permissible speed (rpm, /min, min

-1

) marked on

each tool may never be exceeded.

Router bits may only be operated in the highest spindle speed

(8000 rpm).

The sanding spindle may only be operated in the lowest

spindle speed (1700 rpm).

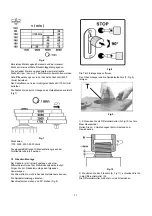

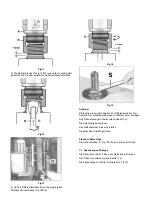

The speed is set by changing the V-belt location on the

pulleys (Fig 7).

Fig 7

Speed range:

1700, 3500, 6000, 8000 RPM

The chosen spindle speed can be seen on the viewing

window.

Summary of Contents for JWS-34KX

Page 44: ...A 1 A 2 A 3 A 4 A 5 ...