Mains

1~230V, PE, 50Hz

Output power

1,5 kW (2 HP) S1

Reference current

10 A

Extension cord (H07RN-F):

3x1,5mm²

Installation fuse protection

16A

Mains

3~400V, PE, 50Hz

Output power

2.2 kW (3 HP) S1

Reference current

5 A

Extension cord (H07RN-F)

4x1,5mm²

Installation fuse protection

16A

Insulation class

I

4.3 Noise emissions

Measurement made in accordance with ISO 19085-6:2017

Operating conditions:

Pine wood, W=100mm, L=1000mm, moisture 8,5%

Rabbet milling head, 125x50x30mm, 2 knives, 8000rpm

Manual feeding operation

A-weighted sound power level :

(for measurement using EN ISO 3746:2010)

Idling

LwA 83 dB(A)

Operating

LwA 90 dB(A)

Associated uncertainty

KwA 4dB

A-weighted emission sound pressure level :

(for measurement using EN ISO 11202:2010)

Idling

LpA 74 dB(A)

Operating

LpA 83 dB(A)

Associated uncertainty

KpA 4dB

The specified values are emission levels and are not

necessarily to be seen as safe operating levels. Although

there is a correlation between emission and imission levels,

these do not constitute a basis for determining the necessity

of additional safety measures.

Workplace conditions which could influence the noise imission

level include the duration of resonance, space particulars,

other noise sources etc. For example, the number of

machines and other work being performed. The permissible

workplace levels can vary from country to country.

This information is intended to allow the user to make a better

estimation of the hazards and risks involved.

4.4 Dust emission

The wood shaper JWS-34KX has been dust emission

inspected.

At an air velocity of 20 m/s on the dust port dia 100mm:

Vacuum pressure

800 Pa

Volume flow

565 m³/h

The machine meets the present workplace dust emission limit

of 2 mg/m³.

4.5 Content of delivery

30mm spindle arbour assembly

Collets 8mm and 12mm

Fence assembly

Spacer board for fence

Shaper guard (workpiece hold downs)

Push stick

Curved guard assembly

Mitre gauge

Operating tools

Assembly kit

Operating manual

Spare parts list

5. Transport and start up

5.1 Transport and installation

For transport use a forklift or hand trolley. Make sure the

machine does not tip or fall off during transport.

The machine is designed to operate in closed rooms and must

be placed stable on firm and levelled ground.

The machine is heavy and therefore stable, it can be bolted

down if required (Fig 3.1).

Fig 3.1

For packing reasons the machine is not completely

assembled.

5.2 Assembly

If you notice any transport damage while unpacking, notify

your supplier immediately. Do not operate the machine!

Dispose of the packing in an environmentally friendly manner.

Clean all rust protected surfaces with a mild solvent.

Mount the handle to the hand wheel.

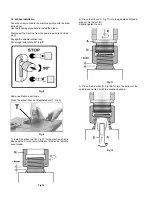

Mount the shaper guard with the two screws supplied (D, Fig

3.2) to the shaper fence top. To lift the shaper guard push the

handle backwards.

Summary of Contents for JWS-34KX

Page 44: ...A 1 A 2 A 3 A 4 A 5 ...