Fig 3.2

5.3 Mains connection

Mains connection and any extension cords and plugs used

must comply with the information on the machine licence

plate.

The mains connection must have a 16A surge-proof fuse.

Only use extension cords marked H07RN-F, with wires

1,5mm

2

or more.

Power cords and plugs must be free from defects.

Connections and repairs to the electrical equipment may only

be carried out by qualified electricians.

ATTENTION:

-Check first if the spindle rotates freely and if all safety devices

are fitted before starting the machine.

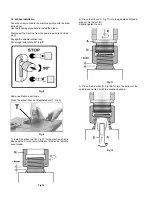

Make sure that the spindle is running the correct direction

(counter-clockwise).

- If the direction of rotation is not correct, the phase converter

inside the CCE Euro plug must be pushed in and turned 180°.

(See rotation arrow on machine for correct rotation, Fig 3.3)

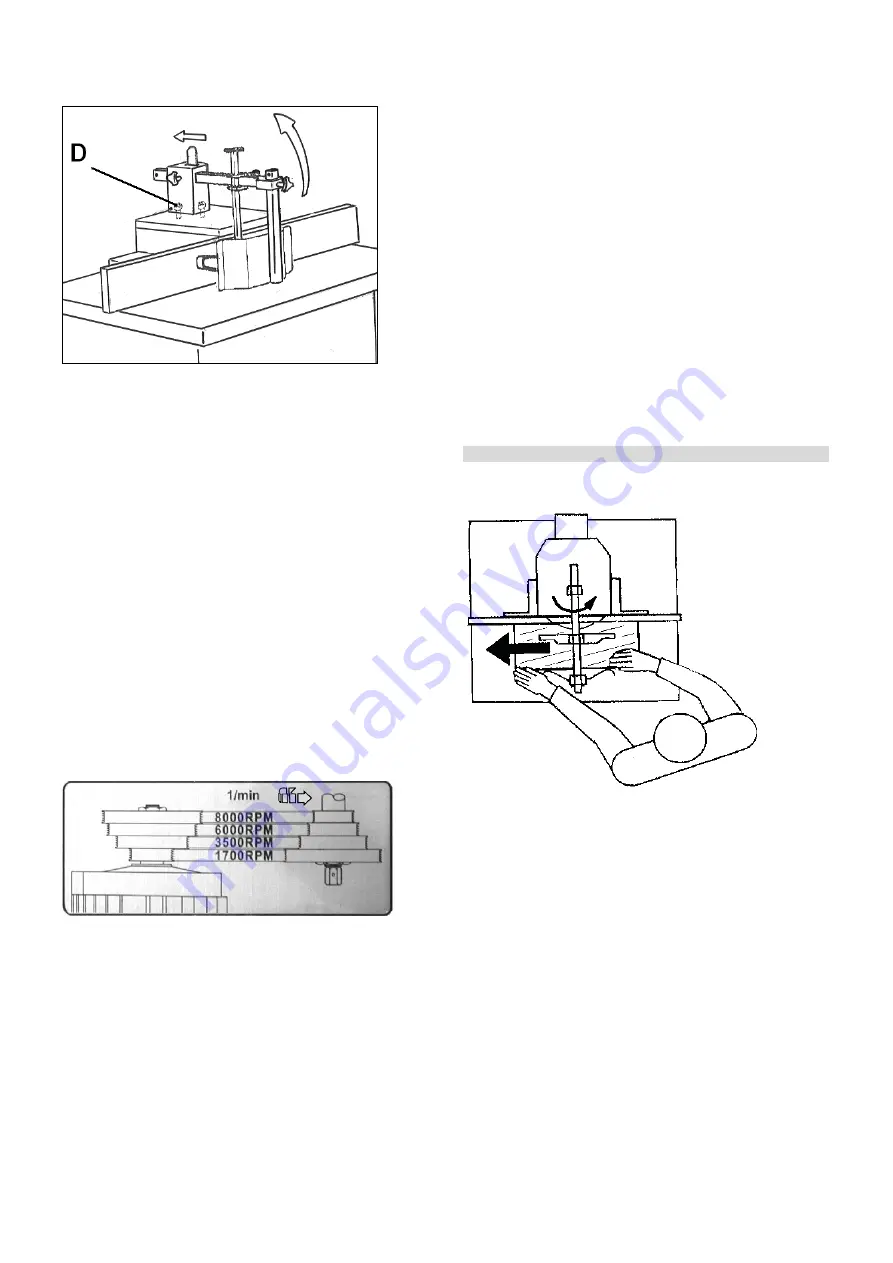

Fig 3.3

5.4 Dust connection

Before initial operation, the machine must be connected to a

dust extractor. The suction should switch on automatically

when the shaper is switched on.

The flow rate on the suction port must be 20m/sec.

Flexible hoses must be of “non-flammable” quality, and must

be connected to the machine ground system.

Reduction of dust exposure:

Exposure to high levels of airborne dust can damage your

health.

Use a suitable dust extraction system (see chapter 4.4 for

minimum volume flow and vacuum pressure).

Avoid long / angled suction lines as these reduce the volume

flow considerably.

Make sure the room is well ventilated.

Use respiratory protection.

5.5 Starting operation

You can start the machine with the green on button. The red

button on the main switch stops the machine.

In case of overload the motor overload cut-off will react. After

approximately 10 minutes of cooling the machine can be

started again.

6. Machine operation

Correct operating position:

Position yourselves offset to the machine front (Fig 4).

Fig 4

Workpiece handling:

Feed the workpiece straight across the machine table, holding

your fingers close together, guiding the workpiece with the

palm of your hands.

Never put your hands under or behind the shaper guard.

Always keep your hands well clear of the rotating cutter.

Always feed the workpiece against the cutter rotation (Fig 4).

Use a push block when working the ends of narrow stock.

Use a feeding aid if you are going to work a workpiece shorter

than 300mm.

Always machine the workpiece over its entire length.

Recess machining may only be carried out with the aid of

suitable longitudinal workpiece stops (Fig 5) ….high danger of

kickback!!!

Summary of Contents for JWS-34KX

Page 44: ...A 1 A 2 A 3 A 4 A 5 ...