Connection and repair work on the electrical installation may

be carried out by a qualified electrician only.

Do not stand on the machine.

Have a damaged or worn power cord replaced immediately.

Make all machine adjustments or maintenance with the

machine unplugged from the power source.

3.3 Remaining hazards

When using the machine according to regulations some

remaining hazards may still exist.

Touching the cutting tool in the machining area can cause

injury. For effective protection the shaper guard must always

be adapted to the workpiece and to the machining operation.

Risk of kickback. The workpiece is caught by the rotating

cutter and thrown back to the operator.

Thrown workpiece parts can lead to injury.

Sawdust and noise can be health hazards.

Be sure to wear personal protection gear such as safety

goggles and ear protection. Use a suitable dust exhaust

system.

The use of incorrect mains supply or a damaged power cord

can lead to injuries caused by electricity.

4. Machine specifications

4.1 Machine description

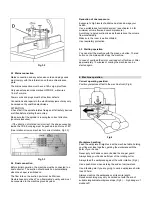

Fig 1

A Shaper guard lock

B Shaper fence

C Fence boards

D Mitre gauge

E Spindle rotation lock

F Spindle up/down lock

G Speed select viewing window

H Motor/pulley access door

I Spindle up/down scale

J Spindle up/down handwheel

K ON/OFF main switch

L Shaper guard, lateral hold down

M Shaper guard, vertical hold down

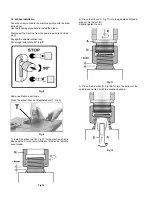

Fig 2

N Fence attachment knobs

O Fence board offset scale

P Fence board lock

Q Fence board offset lock

R Fence board offset adjust knob

S Dust port

T Fence cover lock knob

4.2 Technical data

No-load spindle speed n

o

1700/3500/6000/8000 rpm

Table size

635 x 600 mm

Table height above floor

850mm

Spindle diameter

30mm

Clamped height

70mm

Spindle travel

80mm

Router bit collet size

8 and12mm

Table opening diameter

160mm

Max. tool diameter

180mm

Max. tool height above table

120mm

dust port diameter

100mm

Dimemsions LxWxH

920x680x1090mm

Net weight

156 kg

Summary of Contents for JWS-34KX

Page 44: ...A 1 A 2 A 3 A 4 A 5 ...