7/8

Power is off alarm

Please wait for 30 seconds, then turn on the power switch

Safety switch alarm

Please check the trimming cutter is back the original place, after checking

still safety alarm, please adjust the sensor holder, if still cannot solved,

please enter P66 parameter change from 2 to 0.

SLEEP

D

ormancy

Shut down the system power supply, 30 seconds to connect the power

supply, controller, if still doesn't work, please replace the controller and notify

the manufacturer.

3.4 Error

mode

If the error code appears, please check the following items first:

1.Make sure the machine has been connected correctly; 2.

Confirm that the control box match with the

machine head. 3. Confirm factory reset is accurate

Error Code

Description

Solution

E r r - 0 1

Hardware overcurrent

Turn off the power switch, and restart after 30 seconds. If the controller still does not

work, please replace it and inform the manufacturer.

E r r - 0 2

Software flow

E r r - 0 3

Under-voltage

Disconnect the power to the controller; check the input power supply voltage is low or

not (less than 176V). If the power supply voltage is low, please start the controller after

recovers the voltage. If the controller still does not work, please inform the

manufacturer and replace the controller.

E r r - 0 4

Over-voltage when the

machine is off

Disconnect the controller power and check if the input voltage is too high (higher than

264V). If yes, please restart the controller when the normal voltage is resumed. If the

controller still does not work when the voltage is at normal level, please replace the

controller and inform the manufacturer.

E r r - 0 5

Over-voltage in operation

E r r - 0 6

Solenoid circuit fault

Turn off the system power. Check carefully, if the solenoid connection is loose or

damage, please change it in time. Then restart the system after confirmation, if it still

does not work, please inform the manufacturer and replace the controller.

E r r - 0 7

Motor current measuring

failure

Turn off the system power, restart after 30 seconds to see if it works well. If such failure

happens frequently, seek technical support.

E r r - 0 8

Sewing motor blocked

Turn off the system power. Check whether the motor power input plug is off, loose or

broken, or there is something tangled on the machine head. Please make them correct

then restart the system. If it still does not work, please inform the manufacturer and

replace the controller.

E r r - 0 9

Brake circuit fault

Turn off the system power. Check carefully, if white braking resistor connector on the

power board is loose or fall off, please plug it tight then restart the system, if it still does

not work, please inform the manufacturer and replace the controller.

E r r - 1 0

Communication failure

Check carefully, if the connection between the control panel and controller is off, loose,

or broken, please make it correct then restart the system, if it still does not work, please

inform the manufacturer and replace the controller.

E r r - 1 1

Machine head needle

positioning failure

Check if the connection line between machine head synchronizer and controller is

loose or not, restore it and restart the system. If it still does not work, please replace the

controller and inform the manufacturer.

Summary of Contents for JK-K4-UT

Page 1: ......

Page 2: ...0 51 1 1 YKXOKY YK SGT GR...

Page 22: ...20 51...

Page 36: ...34 51 YKZ YIXK IXGTQ JOYQ JXO K IUTTKIZOTM XUJ T Z T Z...

Page 40: ...38 51 Moving cutter is parallel to the fixed cutter Screw1 Screw3 Screw4 Screw2 Fixed cutter...

Page 41: ...39 51 JP YZ IROV GTJ VXKYY XK YNKKZ clip Pressure sheet clip is parallel to the fixed cutter...

Page 47: ...45 51...

Page 48: ...46 51 SS...

Page 50: ...48 51...

Page 52: ...50 51...

Page 53: ...f 9 g g g g g g g g g g...

Page 54: ...1 11 2 12 13 14 15 16 17 8 8 8 8 8 8 8 8...

Page 55: ...3S...

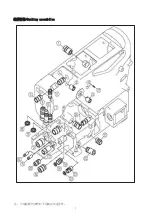

Page 68: ...XVKLQJ DVVHPEOLHV...

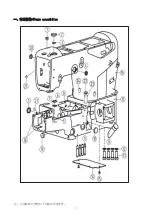

Page 70: ...UDPH DVVHPEOLHV...

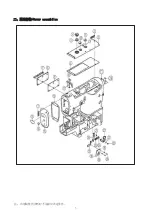

Page 72: ...RYHU DVVHPEOLHV...

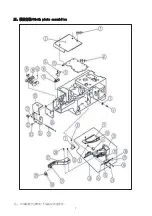

Page 74: ...ORWK SODWH DVVHPEOLHV...

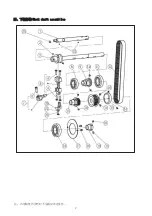

Page 76: ...RRN VKDIW DVVHPEOLHV...

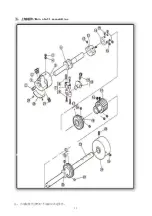

Page 78: ...0DLQ VKDIW DVVHVPEOLHV...

Page 80: ...1HHGOH EDU DVVHPEOLHV...

Page 82: ...1HHGOH JXDUG DVVHPEOLHV...

Page 84: ...HHG PHFKDQLVP...

Page 86: ...1HHG PHFKDQLVP...

Page 88: ...3UHVVHU IRUP DVVHPEOLHV...

Page 90: ...1HHGOH IHHGLQJ DVVHPEOLHV...

Page 92: ...7KUHDG ORRVLQJ DVVHPEOLHV RQH...

Page 94: ...7KUHDG ORRVLQJ DVVHPEOLHV WZR...

Page 96: ...7KUHDG ORRVLQJ DVVHPEOLHV...

Page 98: ...DP DVVHVEOLHV...

Page 100: ...XEULFDWULRQ DVVHPEOLHV...

Page 102: ...2LO SXPS DVVHPEOLHV...

Page 104: ...6LOLFRQ RLO GHOLFH DVVHPEOLHV...

Page 106: ...DXJH VHW VSHFLILF SDUWV...

Page 108: ...QLIH KROGHU DVVHPEOLHV...

Page 111: ...7RS ZLSHU DVVHPEOLHV...

Page 113: ...6ROHQRLG DVVHPEOLHV...

Page 115: ...OHFWURQLF FRQWURO DVVHPEOLHV...

Page 117: ...IWHU FDP DVVHPEOLHV...

Page 120: ...IWHU ILJKW FDP DVVHPEOLHV...

Page 122: ...7KUHDG SRRO VVHPEOLHV...

Page 124: ...35AC 35ACFT device...

Page 126: ...35AC 35ACFT device...

Page 128: ...FFHVVRULHV DVVHPEOLHV...

Page 130: ...HGSODWH DVVHPEOLHV...