8/8

E r r - 1 2

Initial motor electrical angle

failure

- Try 2 to 3 more times after power down

- if it still does not work, please replace the controller and inform the manufacturer.

E r r - 1 3

Motor HALL failure

Turn off the system power, check if the motor sensor plug is loose or dropped off,

restore it and restart the system. If it still does not work, please replace the controller

and inform the manufacturer.

E r r - 1 4

DSP Read/Write EEPROM

failure

Turn off the system power, restart the system after 30 seconds, if it still does not work,

please replace the controller and inform the manufacturer.

E r r - 1 5

Motor over-speed protection

E r r - 1 6

Motor reversion

E r r - 1 7

HMI Read/Write

EEPROM failure

E r r - 1 8

Motor overload

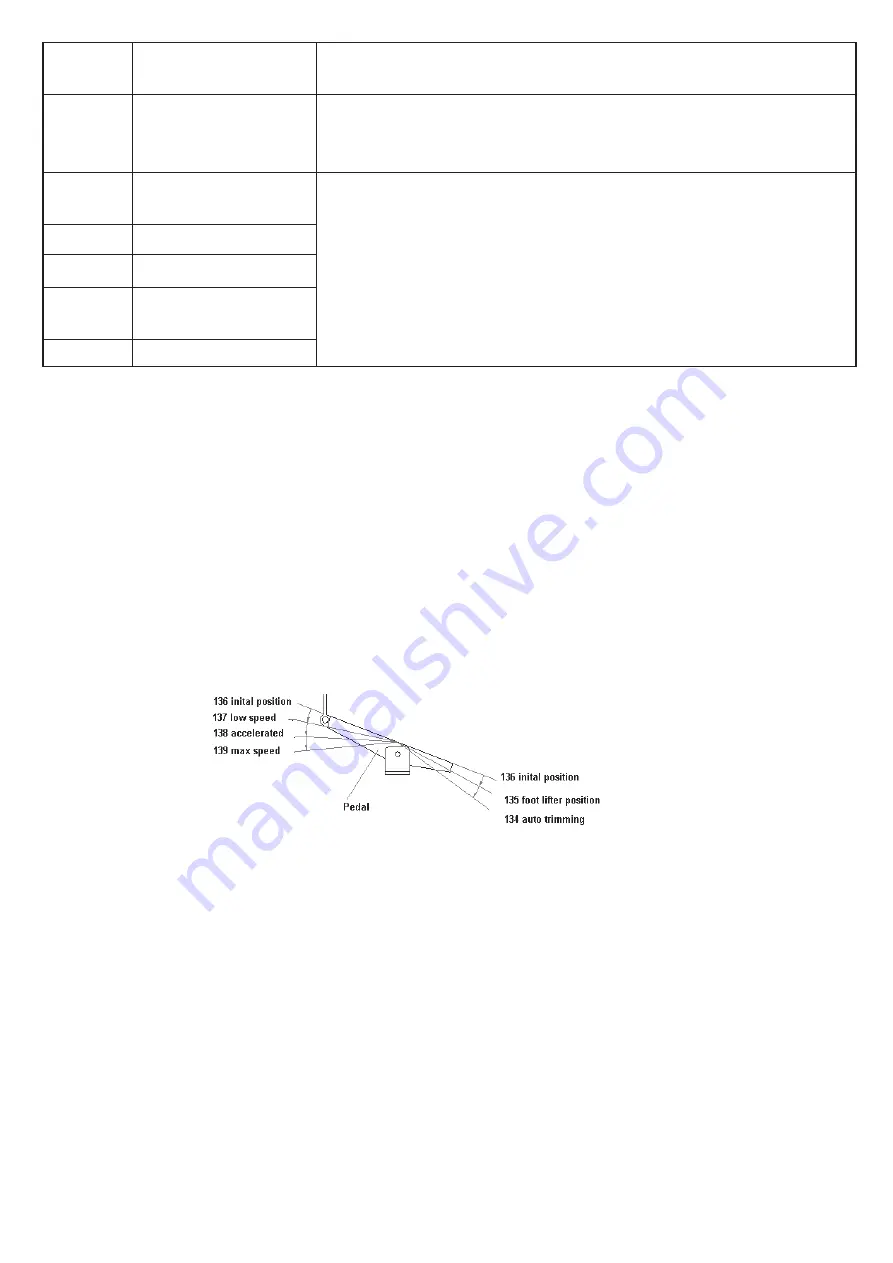

4 Pedal sensitivity adjustment

Pedal movement starts from the initial position (p.136) where the motor stops, slowly stepped forward to the

low speed point (p.137) where the motor runs at the minimum speed (p.100), proceeding to the accelerated point

(p.138) where the motor start fasten, until the max speed point (p.139) where the motor run up to the maximum

speed (p.101). And when the pedal steps back to the foot lifter position (p.135), the automatic presser foot lifting.

Continuing back to the auto trimming position (p.134), thread trimming is completed automatic. The parameter

value is set for an assurance (No. 134 parameters) < (No. 135 parameter) <( No. 136 parameters) <( No. 137

parameters) <( No. 138 parameters) <( No. 139 parameters). Adjusting the corresponding parameters, user can

acquire the proper pedal response to fit the personal habit.

Fig. 4-1 pedal movement of each position parameter

3)

Summary of Contents for JK-K4-UT

Page 1: ......

Page 2: ...0 51 1 1 YKXOKY YK SGT GR...

Page 22: ...20 51...

Page 36: ...34 51 YKZ YIXK IXGTQ JOYQ JXO K IUTTKIZOTM XUJ T Z T Z...

Page 40: ...38 51 Moving cutter is parallel to the fixed cutter Screw1 Screw3 Screw4 Screw2 Fixed cutter...

Page 41: ...39 51 JP YZ IROV GTJ VXKYY XK YNKKZ clip Pressure sheet clip is parallel to the fixed cutter...

Page 47: ...45 51...

Page 48: ...46 51 SS...

Page 50: ...48 51...

Page 52: ...50 51...

Page 53: ...f 9 g g g g g g g g g g...

Page 54: ...1 11 2 12 13 14 15 16 17 8 8 8 8 8 8 8 8...

Page 55: ...3S...

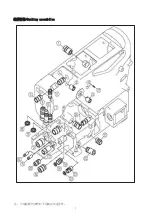

Page 68: ...XVKLQJ DVVHPEOLHV...

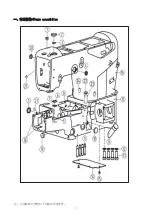

Page 70: ...UDPH DVVHPEOLHV...

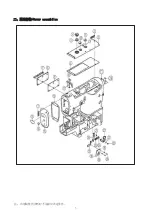

Page 72: ...RYHU DVVHPEOLHV...

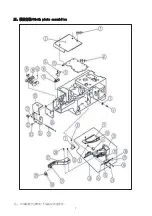

Page 74: ...ORWK SODWH DVVHPEOLHV...

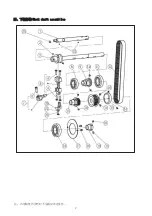

Page 76: ...RRN VKDIW DVVHPEOLHV...

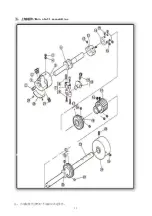

Page 78: ...0DLQ VKDIW DVVHVPEOLHV...

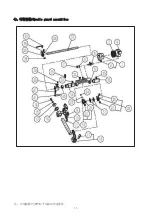

Page 80: ...1HHGOH EDU DVVHPEOLHV...

Page 82: ...1HHGOH JXDUG DVVHPEOLHV...

Page 84: ...HHG PHFKDQLVP...

Page 86: ...1HHG PHFKDQLVP...

Page 88: ...3UHVVHU IRUP DVVHPEOLHV...

Page 90: ...1HHGOH IHHGLQJ DVVHPEOLHV...

Page 92: ...7KUHDG ORRVLQJ DVVHPEOLHV RQH...

Page 94: ...7KUHDG ORRVLQJ DVVHPEOLHV WZR...

Page 96: ...7KUHDG ORRVLQJ DVVHPEOLHV...

Page 98: ...DP DVVHVEOLHV...

Page 100: ...XEULFDWULRQ DVVHPEOLHV...

Page 102: ...2LO SXPS DVVHPEOLHV...

Page 104: ...6LOLFRQ RLO GHOLFH DVVHPEOLHV...

Page 106: ...DXJH VHW VSHFLILF SDUWV...

Page 108: ...QLIH KROGHU DVVHPEOLHV...

Page 111: ...7RS ZLSHU DVVHPEOLHV...

Page 113: ...6ROHQRLG DVVHPEOLHV...

Page 115: ...OHFWURQLF FRQWURO DVVHPEOLHV...

Page 117: ...IWHU FDP DVVHPEOLHV...

Page 120: ...IWHU ILJKW FDP DVVHPEOLHV...

Page 122: ...7KUHDG SRRO VVHPEOLHV...

Page 124: ...35AC 35ACFT device...

Page 126: ...35AC 35ACFT device...

Page 128: ...FFHVVRULHV DVVHPEOLHV...

Page 130: ...HGSODWH DVVHPEOLHV...