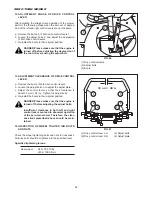

IMPORTANT:

•

When a fuse or a slow-blow fuse is blown, be sure to

locate the trouble and correct it. When the couse is not

clear, consult your dealers.

•

Be sure to use specified fuses. Larger-capacity fuses

will cause burn-out of electric accessories and wiring.

•

When a slow-blow fuse has been burnt out, use gen-

uine slow-blow fuse

The alternator and the starter motor have their

own slow-blow fuse.

WARNING:

• Damaged wire covers should be mended

with insulation tape immediately.

CAUTION:

• The wiring of the Zero turn mower should

be checked every year at your dealers to

avoid electrical fires.

• Grass and dust around the battery, wiring,

muffler and engine ahould be removed.

Otherwise they may catch fire.

IMPORTANT:

•

When a wire harness has come off its clamp, it should

be re-clamped immediately.

25. MAINTENANCE OF HYDRAULIC SYSTEM PARTS

When hydraulic system parts such as the HST unit,

hydraulic pump, control valve, hydraulic cylinder, pip-

ing, etc. are required to be adjusted or repaired, con-

sult your ISEKI dealers. Users are advised not to

adjust or repair hydraulic system parts by themselves.

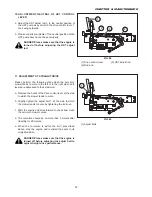

26. INSPECTION OF SAFETY SWITCHES

Safety devices are installed for safe operation. Make

certain that each device works properly before opera-

tion following the next procedures.

CAUTION:When the engine does not start

due to a defective safety swtich or does not

stop even when the operator leaves his seat,

ask your dealer for repair immediately.

INSPECTION 1

a. Be seated in the operator's seat.

b. Turn the PTO switch to the ON (

M

) position.

c. Set the drive control lever to the neutral open-lock

position.

d. Depress the brake pedal.

e. Turn the key switch to the START (

c

) position.

f. Make sure that the engine is not cranked.

INSPECTION 2

a. Be seated in the operator's seat.

b. Shift the PTO lever to the OFF (

N

) position.

c. Set the drive control lever to the drive position.

d. Depress the brake pedal.

e. Turn the key switch to the START (

c

) position.

f. Make sure that the engine is not cranked

INSPECTION 3

a. Be seated in the operator's seat.

b. Turn the PTO switch to the OFF (

N

) position.

c. Set the drive control lever to the neutral open-lock

position.

d. Don't depress the brake pedal.

e. Turn the key switch to the START (

c

) position.

f. Make sure that the engine is not cranked.

INSPECTION 4

a. Be seated in the operator's seat.

b. Turn the PTO switch to the OFF (

N

) position.

c. Set the drive control lever to the neutral open-lock

position.

d. Depress the brake pedal.

e. Turn the key switch to the START (

c

) position.

f. Make sure that the engine is cranked and started.

g. Apply the parking brakes.

h. Leave from the operator's seat.

i. Make sure that the engine working continue.

j. Close the drive control lever and check if the buzzer

sounds off. The engine should stop after 1 second.

INSPECTION 5(ONLY FOR F2-TYPE)

a. Be seated in the operators's seat.

b. Turn the PTO switch to the OFF (

N

) position.

c. Set the drive control lever to the neutral open-lock

position.

d. Depress the brake pedal.

e. Turn the key to the START (

c

) position.

f. On this condition, make sure that it is not started the

engine with the engine hood is open.

CHAPTER 8. MAINTENANCE

61

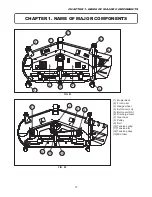

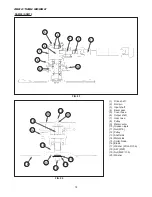

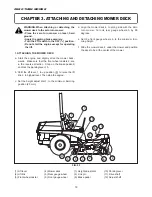

Summary of Contents for SZ330

Page 1: ...I S E K I Z E R O T U R N M O W E R ZERO TURN MOWER MOWER DECKS SZ330 SSM60 SSM72 ...

Page 21: ...20 9 29 Check that all safety devices are in place and oper ating properly ZERO TURN MOWER ...

Page 71: ...ZERO TURN MOWER 70 ...

Page 94: ...95 CHAPTER 7 TROUBLESHOOTING ...

Page 95: ...96 ZERO TURN MOWER ...