39

ISEKI LAWN MOWERS

Fig. 3-63

- Measure cylinder bore diameter at a point of 12

to 14 mm below the cylinder block top surface

in two directions: one is in alignment with the

crankshaft axis and the other is at right angles to

the crankshaft axis.

Wear limit

0.2 mm

- If wear is in excess of 0.2 mm, correct by hon-

ing.

- Honing should be done to fit a oversize piston,

which should be done at a specialist’s workshop.

Oversize

0.5; 1.0 mm

- Honing accuracy should be to the extent that bore

diameters measured in two directions at A and B

and in three levels at a, b, and c differ less than

0.02 mm from each other.

A

B

a

b

c

12 mm

10 mm

Fig. 3-64

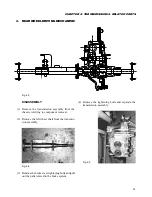

(2) Inspection of the crankshaft

• Check the crankshaft journals for oil clearance.

a. Clean the journals and bearings.

b. Install the upper bearings and crankshaft on the

cylinder block.

c. Put plasti-gauge over the journal width.

Fig. 3-65

d. Install the barings on respective bearing caps.

Install the assembles and tighten them to the

specified torque.

Specified torque

4.5 – 5.5 kgf·m

While tightening, the crankshaft should be held

securely so as not to turn.

e. Loosen the tightening bolts and remove the bear-

ing caps carefully. Then measure the most

stretched parts of the plasti-gauges.

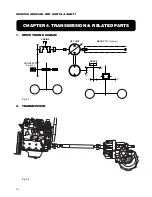

Summary of Contents for SCM49

Page 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Page 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Page 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...