22

SERVICE MANUAL FOR SGR19 & SGR17

Specified deflection

5 – 10 mm

Fig. 3-4

• Adjustment:

When the deflection is more than specified, ten-

sion the belt properly by moving the alternator.

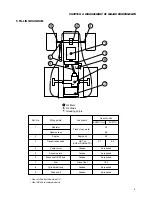

3. INSPECTION AND ADJUSTMENT OF

VALVE CLEARANCES

3.1. Remove the cylinder head cover.

3.2. Turn the crankshaft by hand so that the piston in

No.1 cylinder reaches at TDC: align the

TDC notch in the crankshaft pulley with the pro-

jection on the gear case.

Direction

of rotation

TDC

Injection

timing

Crankshaft

pulley

Fig. 3-5

Note:

When it is difficult to distinguish between TDC

in compression stroke and TDC in exhaust stroke,

use height difference among the push rods as a

criterion for judgement. When the heights of the

push rods (No.1, 2,3, and 6 viewed from the fan)

are about 5 mm lower than those of No.4 and 5,

the piston in No. 1 cylinder is at TDC in com-

pression stroke.

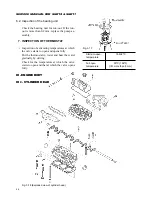

3.3. Insert a feeler gauge of a specified thickness and

adjust the clearance with the adjusting screw.

Specified valve clearance (cold):

Intake

0.25 mm

Exhaust

0.25 mm

Fig. 3-6

4. INSPECTION AND ADJUSTMENT OF

NOZZLE OPENING PRESSURE AND IN-

JECTION TIMING

4.1. Adjustment of the valve opening pressure

of the injection nozzles

• Measure the pressure of initial fuel injection on

a nozzle tester.

E393-G & E383-G:

Specified pressure

120 kg/cm

2

Fig. 3-9

Summary of Contents for SCM49

Page 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Page 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Page 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...