31

CHAPTER 3. ENGINE

Fig. 3-37

(3) Inspection of the rocker arm shaft for wear

• Measure diameter at four points where the shaft

bears respective rocker arms.

• When wear is in excess of the usable limit, re-

place the shaft.

Standard value

Usable limit

Diameter

16.00 mm

15.85 mm

Fig. 3-38

4) Inspection of the clearance between the rocker

arms and rocker arm shaft

• Measure the bore diameter of each rocker arm

and calculate the difference from the diameter

of the rocker arm shaft.

When the difference exceeds the usable limit,

replace the assembly of the rocker arm shaft and

rocker arms.

Fig. 3-35

Usable limit

Surface flatness (both for intake

0.2 mm

and exhaust manifolds)

When the deviation exceeds the usable limit,

replace the manifold.

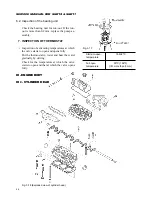

4. DISASSEMBLY AND INSPECTION OF

THE ROCKER ARM SHAFT

(1) Disassembly of the rocker arm shaft assembly

• Put an identification mark on the front side top

of the rocker arm shaft for later reference.

• Remove snap rings C and remove arm brackets.

• Put away the brackets in order.

Fig. 3-36

(2) Inspection of the rocker arm shaft for bending

• Check for bending with a dial gauge.

Usable limit

Shaft bending

0.5 mm

Summary of Contents for SCM49

Page 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Page 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Page 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...