50

Ioline FJ Printer & StudioJet Service Manual

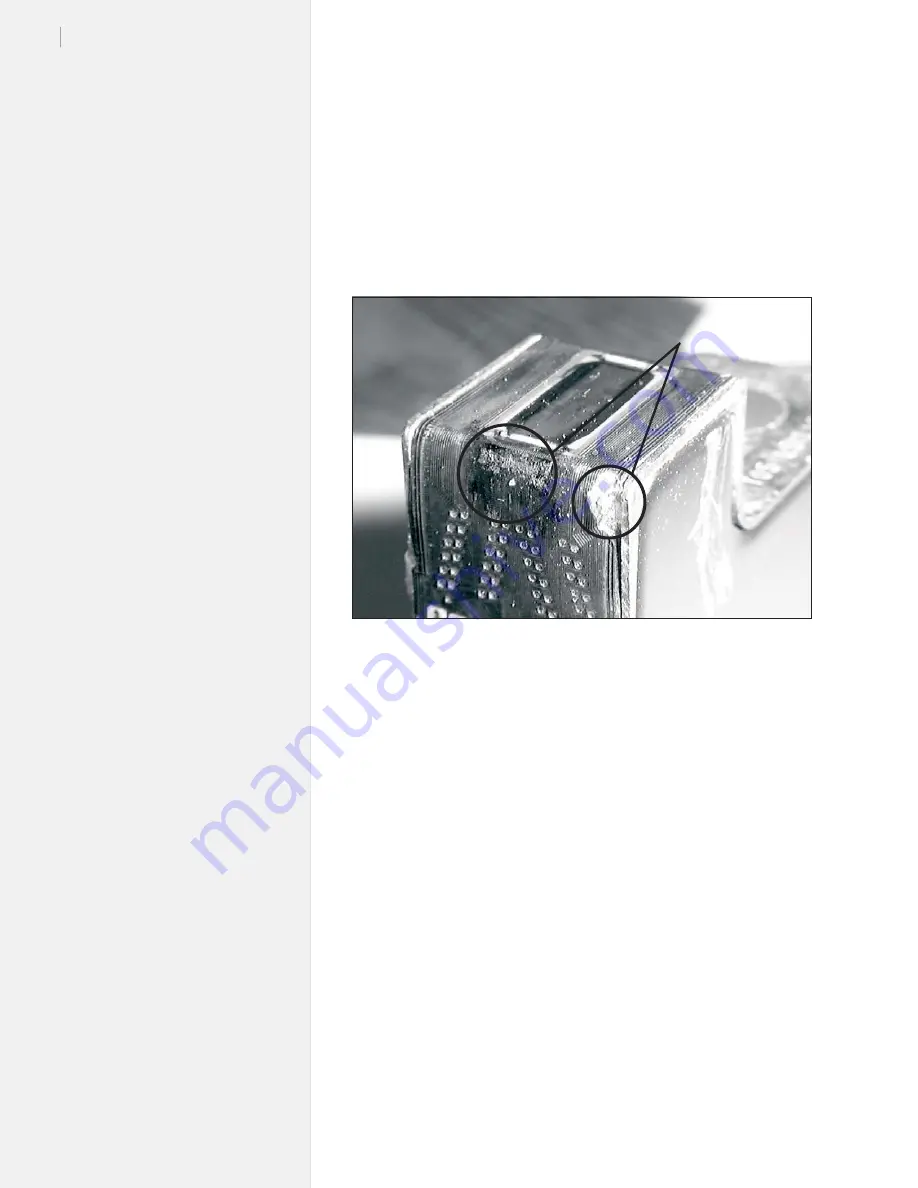

Figure 26.

Damaged and dirty print cartridge.

Dirty or damaged cartridge

Sometimes a cartridge will go bad for no apparent reason. The

cartridge may look perfect and be full of ink, but it will not plot. If

this occurs

fi

rst try pressing the Clean button on the keypad. Install a

new cartridge and the tests to see if this

fi

xes the problem.

If this has no effect remove, clean, inspect for damage, then test. If

the cartridge fails again replace it.

Broken circuit

from mishandling

Cartridge calibration

The

Cartridge Calibration

window is located in the

Control Center

and can be accessed in the

Tools

menu. Step-by-step instructions on

the calibration process are provided in the

User Guide

.

The examples below show different results and settings of the car-

tridge calibration window. If the printer is printing poorly, check

some of the examples here for a possible

fi

x.

Calibration overview

Cartridge Alignment:

Aligns the ink cartridges with each other.

On 1-head machines, cartridge calibration is

not neccessary.

Motion Adjustment:

Aligns (side to side) each pass of the car-

riage with the next pass.

Frame Gap:

Aligns (from top to bottom) each pass of the

carriage.

Summary of Contents for FJ Printer

Page 1: ...Service Manual Ioline FJ Printer StudioJet ...

Page 3: ...Service Manual Ioline FJ Printer StudioJet ...

Page 4: ......

Page 7: ......

Page 8: ......

Page 12: ......

Page 36: ...36 Ioline FJ Printer StudioJet Service Manual This page intentionally left blank ...

Page 61: ...61 Chapter 3 Troubleshooting Testing This page intentionally left blank ...

Page 66: ...66 Ioline FJ Printer StudioJet Service Manual This page intentionally left blank ...

Page 75: ...75 Chapter 4 Repair Procedures This page intentionally left blank ...

Page 87: ...87 Chapter 4 Repair Procedures Photo 4 Photo 5 Photo 6 ...

Page 92: ...92 Ioline FJ Printer StudioJet Service Manual This page intentionally left blank ...

Page 110: ...110 Ioline FJ Printer StudioJet Service Manual This page intentionally left blank ...