Select this preset from the list, click

Apply

in the Selected Preset group and then click

Test

. If the

shaft does not make a 360° turn you will have to adjust this parameter manually. Do experiment.

The 360° turn should be within the 205-235µs range.

Should you require a different angle, here are some Turn Offset values for reference:

- a Turn Offset of ~120 µs will result in a 180° turn,

- a Turn Offset of ~435 µs will result in two whole turns (720°).

3.2.2. Overcurrent Protection

Note:

do NOT change this parameter if you have no prior experience. Before changing this

parameter make sure you read and understand this chapter.

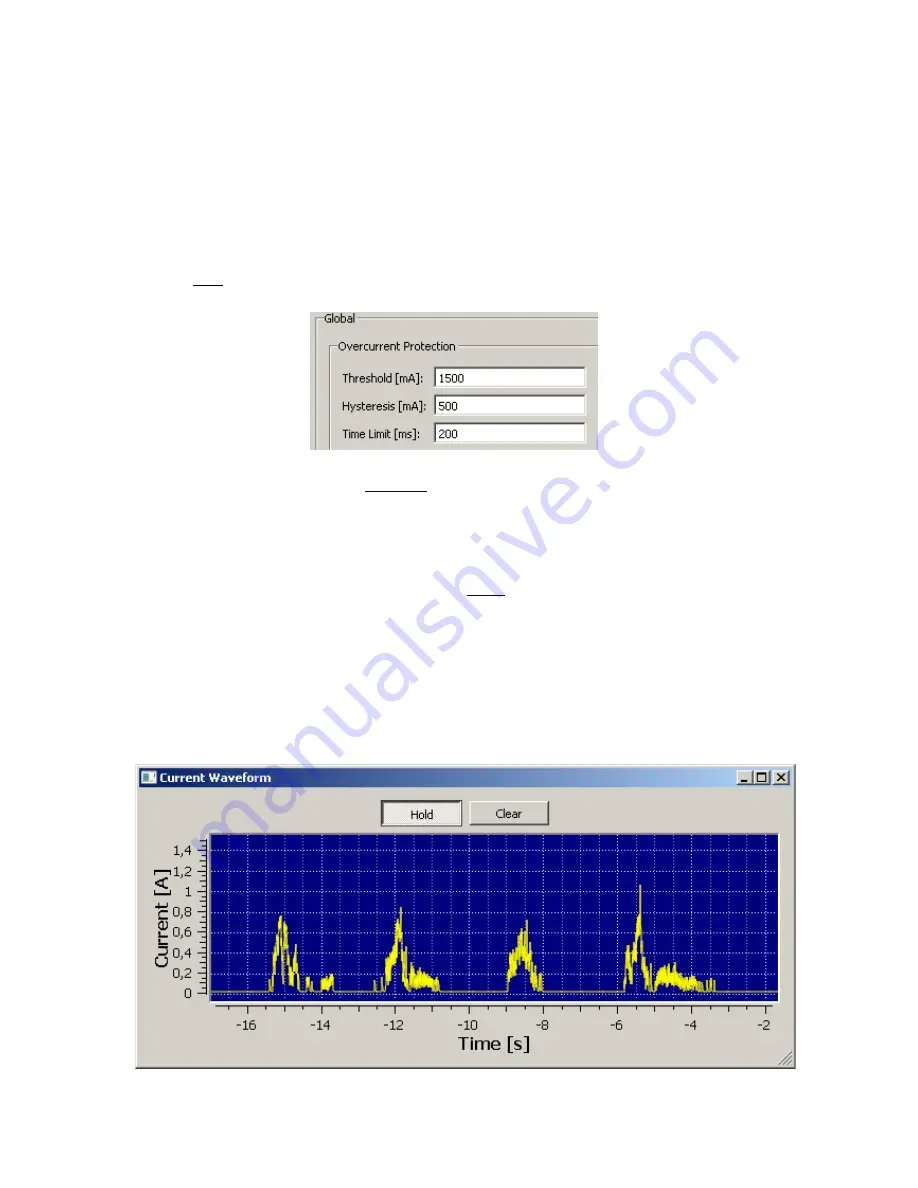

Fig. 15

Default overcurrent protection settings

The aim of overcurrent protection (

Fig. 11-A

) is to protect the drive and electronics from damage.

The motor draws high currents when:

a) the drive gets blocked – this usually happens when the camera hits the landing gear

during operation or something gets stuck between the pulleys and the belt,

b) the load is high and the driving parameters are too aggressive – a heavy camera is used

and the Acceleration and Max. Speed parameters (

Tab.2

) are too high for the load.

Pano360 electronics has the ability to detect high currents that are drawn by the servo in

the above scenarios.

If, during operation, the current value exceeds the Threshold and does not

drop below Threshold minus Hysteresis within the Time Limit then the motor will be turned off

and that should hopeful protect Pano360 from damage.

You can view the current waveforms by clinking

Current Waveform

at the GUI bottom.

Current waveform show how much current is drawn over time by the servo motor during

operation.

Fig. 16

Waveform example, Number of steps=4, Acc.:500, Dec:500, Max Speed:500, Load: 1.6 kg

Step 1

Step 2

Step 3

Step 4