31

P

R

E

V

M

A

I

N

T

E

N

A

N

C

E

5

L

T

R

C

O

M

P

R

E

B

U

I

L

D

PROCEDURE 2 - PREVENTIVE MAINTENANCE (continued)

PREVENTIVE MAINTENANCE

PROCEDURE 2

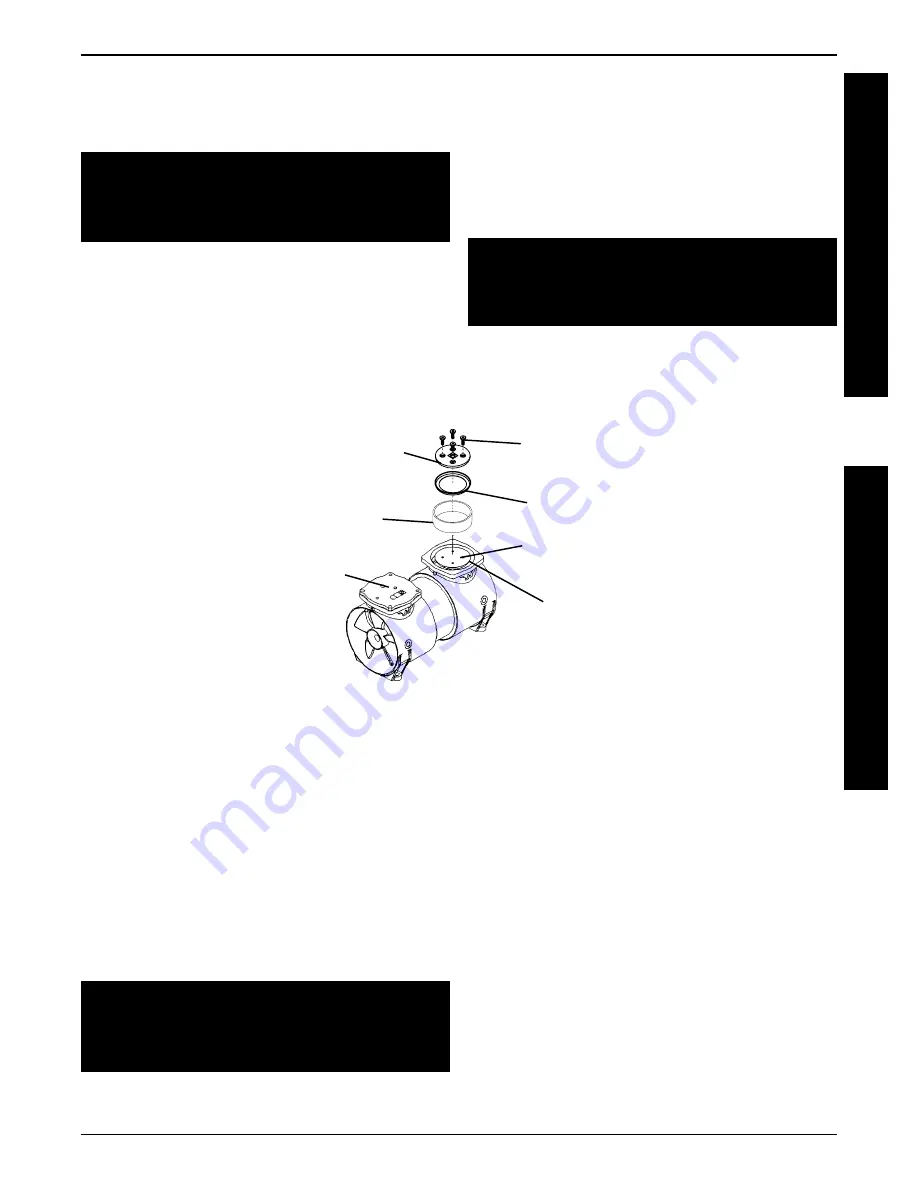

Installing the New Teflon Rings and Piston

Heads (FIGURE 12)

4. Install and tighten the phillips head screws until

snug to align the Teflon ring with the aluminum

sleeve.

5. Once the Teflon ring is centered properly with the

piston head and aluminum sleeve, torque the

screws to 30 in. lbs.

CAUTION

Piston head MUST be rotated 90

O

when rein-

stalling. This ensures proper wear on the pis-

ton head and will prolong it's life.

1. Place the aluminum sleeve onto its mounting

position on the compressor housing.

2. Rest the new Teflon ring on the aluminum sleeve

and center the ring with the piston head.

3. Install the piston head over the piston ring and

into the aluminum sleeve.

One (1) Piston

Rebuild ONLY

SHOWN for Clarity

Phillips Head

Screws

(4 per Head)

Piston

Teflon Ring

Aluminum Sleeve

Piston Head

Valve Plate

FIGURE 12 - INSTALLING THE NEW TEFLON RINGS AND PISTON HEADS

Mounting Position for

Aluminum Sleeve

CAUTION

DO NOT force aluminum sleeve onto piston. The

Teflon ring may become damaged and

render the piston unusable.

Installing Top and Bottom Flappers (FIGURE

13)

NOTE: Ensure that new valves are facing in the

same direction that the old ones when install-

ing and that they completely cover the compres-

sion opening in the valve plate. Make sure that

no dirt or grease contacts the valves or valve

plates as this may inhibit their ability to open

and close properly and severely reduce the

compressor's ability to adequately compress the

air. Replace the top and bottom valves by doing

one side of the valve plate at a time.

CAUTION

Because of tooling of the valve keepers, ensure

that the word "UP" on the valve keeper is fac-

ing you when installing the valve keepers.

1. Use the small common (flathead) screwdriver

to remove the valve screw securing the valve

restraint, valve keeper, and valve to the top of

the valve plate.

2. Remove the valve screw, valve keeper, and valve

from the bottom side of the valve plate.

3. Reverse STEPS 1-2 to install the NEW top and

bottom valves onto the valve plate.

4. Torque valve screws to 12 in. lbs.

5. Install the head gasket in the compressor head

and the valve plate gasket into the underside of

the valve plate.

6. After the other piston has been rebuilt, install the

valve plates over the aluminum sleeves and rein-

stall the head assembly onto the valve plates not-

ing the markings made when the head assembly

and valve plates were removed.

Summary of Contents for 3LX

Page 69: ...69 NOTES N O T E S ...

Page 70: ...70 NOTES N O T E S ...