Interroll Module belt conveyor SH 1100

Maintenance and repair

Version 1.0 (06/2022) en

Translation of original operating instructions

57

Replacing the module conveyor

To operate module conveyors with sprockets requires that a sufficient number of sprockets are

attached to the drum shell in order to support the module conveyor and to correctly transfer the

force.

DANGER

Danger to life from electrocution and crushing

Installation and maintenance tasks on 400-V conveyor systems while they are in operation can

cause life-threatening electrocution and serious crushing.

4

Power down the entire conveyor module and ensure that it cannot be started accidentally.

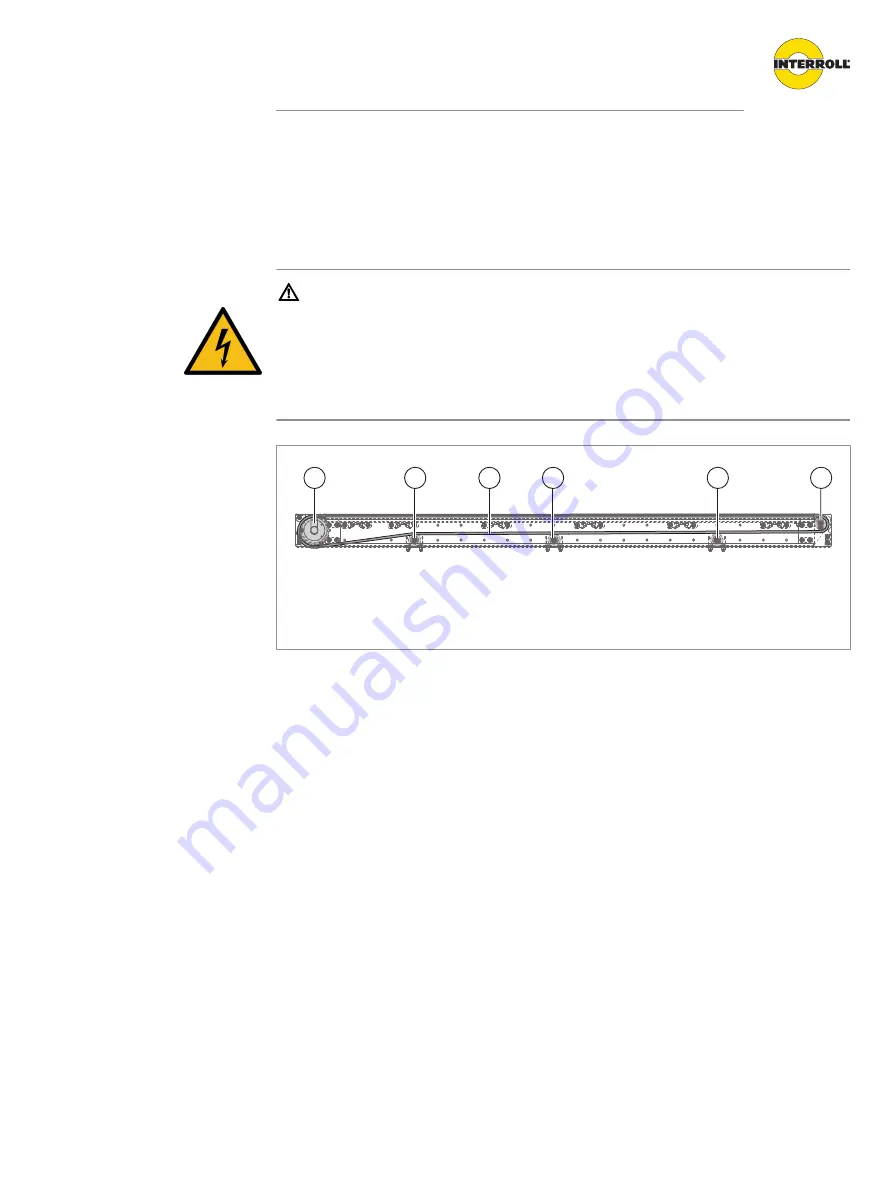

Replacing the module

conveyor (head drive)

1

2

2

3

2

4

Path of module conveyor for head drive

1

Drum motor

3

Module conveyor

2

Return wheel

4

Front idler axle

Requirement:

R

The module is shut down.

4

Remove the end plates,

see "Removing/installing front side idler axle end plate", page 56

"Removing/installing drum motor end plate", page 55

4

Remove the return wheel cover,

see "Removing/installing cover plates at return axles",

4

Drive the connecting rod out of the module conveyor with a hammer and mandrel.

4

Thread out the old module conveyor and properly dispose of it.

4

Guide new module conveyor (3) around sliding guides, front idler axles (4) and drum

motor (1) and thread it in above the return wheels (2).

4

Combine the module conveyor without sagging and drive in the connecting rod using a

hammer and mandrel.

4

Install the end plates and return wheel cover in reverse order.