23

INSTALLATION OF THE CONDENSATE PIPE

1. The condensate pipe should keep a inclination angle of 5 ~

10”, to facilitate the drainage of the condensate water. And

the joints of the condensate pipe should be insulated by the

insulation material to prevent condensing (see Fig. 36).

Insulating Layer for the Condensate Pipe

Pipe Lid

Fig. 36

-

Thermal Insulation of the Condensate Pipe

2. There is a condensate outlet on both the left and right sides of

the unit. Once one is confirmed for use, the other should be

clogged by a rubber plug, bundled by the binding wire and

insulated by the insulation material to avoid water leakage.

3. The right outlet is defaulted to be clogged with a plug.

IMPORTANT

: No water leakage is allowed on the joint of the

condensate pipe.

DESIGN OF THE DRAIN PIPE

1. The drain pipe should always be kept an inclination angle

(1/50~1/100) to avoid water from gathering.

2. During the connection of the drain pipe and device, do not

impose excessive force on the pipe on one side of the device.

Additionally the pipe should be secured closely to the device.

3. The drain pipe can be the ordinary hard PVC pipe which

can be purchased locally. During the connection, inset the

end of the PVC pipe to the drain outlet, then tighten it with

the drain hose and binding wire. Never connect the drain

outlet and the drain hose with adhesive.

4. When the drain pipe is used for multiple devices, the public

section of the pipe should be 4 in (100 mm) lower than the

drain hole of each device and it is better to use the much

thicker pipe for such a purpose.

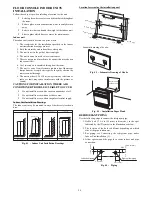

INSTALLATION OF THE DRAIN PIPE

1. The diameter of the drain pipe should be larger than or

equal to that of the refrigerant pipe (PVC pipe, outer

dimater: 1 in (25 mm), wall thickness

0.06 in (1.5 mm).

2. The drain pipe should be a short as possible and with at

least a 1/100 degree of slope to avoid forming air pockets.

3. If the proper degree of slope of the drain pipe is not

allowed, a lift pipe should be installed.

4. A distance of 3.28 ft~4.92 ft (1m~1.5 m) should be kept

between the hangers to avoid the drain hose from making a

turn.

3.28 ft~4.92 ft

(1m~1.5 m)

(Wrong)

Fig. 37

-

Slope Degree

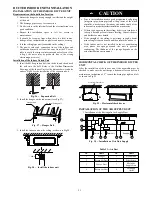

5. Insert the drain hose into the drain hole and tighten it with

clamps.

6. Wrap the clamps with large amount of sponge for thermal

insulation.

7. The drain hose inside the room also should be insulated.

Clamp (accessory)

Sponge (gray)

Drain Hose

Sponge (accessory)

Clamp

(accessory)

Max. 4mm

Fig. 38

-

Drain Hose Insulation

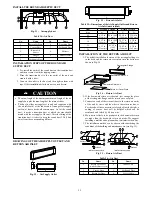

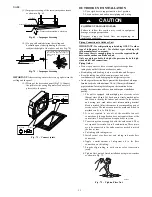

PRECAUTIONS FOR THE LIFT PIPE

The lift pipe install height should be less than 33 1/2 in (850 mm). We

recommend setting an inclination angle 1~ 2

_

for the lift pipe toward

the drainage direction. If the lift pipe and the unit form a right angle,

the height of the lift pipe must be less than 31 1/2 in (800 mm).

1°

2°

1~1.5m

1000mm

850mm

11 4/5 in (300 mm)

150mm

Ceiling

Clamp (accessory)

Drain Hose (accessory)

Lift Pipe

Hanger Bracket

Fig. 39

-

Installation Height

NOTE

:

1. The inclination height of the drain hose should be within 3

in. (75 mm) so that the outlet of the drain hose does not

suffer any external force.

2. If multiple drain pipes converge, follow the installation

steps below.

The specification of the joint of the drain pipe should be suitable to the running capacity of the unit

Drain Hose (accessory)

Max.75mm

Max.1000mm

Fig. 40

-

Multiple Line Convergence