UltraView PTZ

Installation Manual

16

Flush-mount housings

Flush-mount and pendant-mount housings require different preparation of the mounting surface and different

installation procedures of the housings. Follow the instructions given here for flush-mount housings.

Preparing the surface for flush-mounts

Following are the steps for preparing the mounting surface if you are mounting the housing directly into a solid

surface that does not require reinforcement. If the mounting surface does require reinforcement, first install a

GEA-113 T-bar ceiling panel or a GEA-114 T-bar support kit. Instructions for installing the GEA-114 are

available in this manual (

GEA-114 T-bar ceiling support kit

on page 45). If you are installing a GEA-113, refer

to the instructions that came with the panel (1052914).

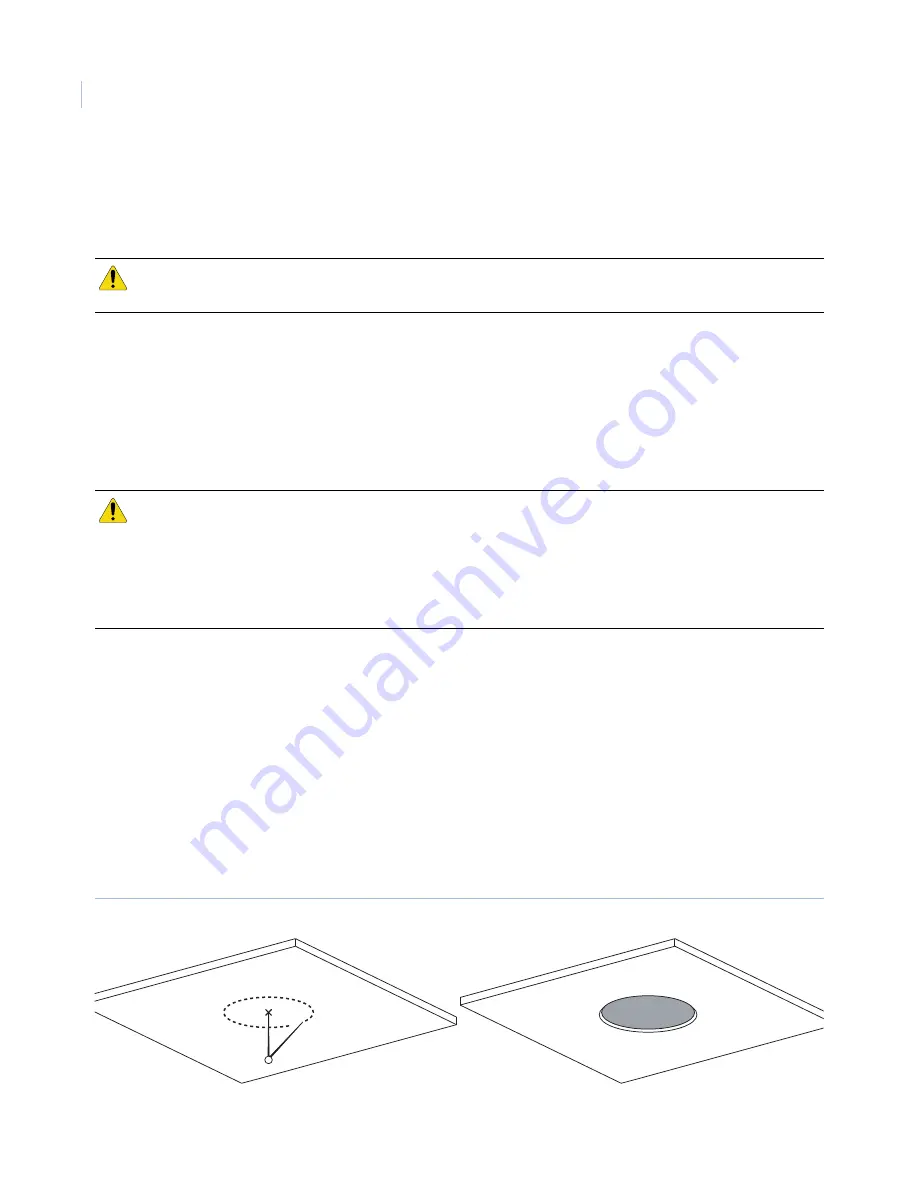

To prepare the mounting surface, see

Figure 12

and do the following:

1. Mark the position and size of the housing passthrough hole on the mounting surface. The size of the

cutout for the passthrough must be 8-3/8 to 8-7/16 in. (21.27 to 21.42 cm).

2. Following all local codes, cut the housing passthrough hole.

3. Make sure that the facility cables (data, video, and power) for the dome comply with the

recommendations provided in

Power requirements

on page 5.

4. Feed the facility cables through the housing passthrough hole in the mounting surface.

•

Pull enough cable to make connections. You can always cut off unneeded length later.

•

How many cables you have depends upon how many video, data, and power cables you are using.

See

Wiring

on page 19.

Figure 12.Preparing the mounting surface for flush-mount housings being mounted into solid surfaces not requiring reinforcement

CAUTION:

The flush-mount housing is for indoor applications only. Do not expose it to moisture, or the unit may

become damaged.

CAUTION:

For all installations, heed these cautions:

•

Complete all installation steps before supplying power to the dome.

•

To ensure proper operation of a PTZ unit, install the mount level.

•

For safety, the mounting surface, hardware, and procedure used for securing the dome

must support the weight of the dome, mount (if used), cables, and any structural or environmental

vibration according to local codes. See

Table 1

on page 4.

Cutout size:

8-3/8 to 8-7/16 in.

(21.27 to 21.42 cm)

Position and size marked

Summary of Contents for UltraView PTZ

Page 1: ...UltraView PTZ Installation Manual...

Page 6: ...UltraView PTZ Installation Manual vi...

Page 10: ...UltraView PTZ Installation Manual x...

Page 18: ...UltraView PTZ Installation Manual 8...

Page 46: ...UltraView PTZ Installation Manual 36...