25

STD

Common Fault Relay

- This is an output provided for customer use. This relay energizes

during normal operation and returns to its Normally Open, N.O., state, when a shutdown or trip

condition is detected. The Fault relay should only toggle when the controller has detected a Shutdown

or Trip (Alarm) condition.

STD

Condensate Drain

- This is an output provided to control a condensate drain solenoid valve.

This output is a timed output that toggles on for a period of time defined by the Condensate Drain

Time set point. The drain valve remains off for a period defined by the Condensate Drain Interval

Time set point.

Condensate Drain Time Default - 5 Sec

Minimum - 1 Sec

Maximum - 30 Sec.

Condensate Interval Time Default - 180 Sec

Minimum - 90 Sec

Maximum - 300 Sec

ENH

Modulation

- The modulation output is used to turn on the modulation solenoid valve anytime

the modulation set point is turned on and the machine is in a loaded state. If the modulation set point

is turned off the output remains off.

1.5

Control Power Supply

- 24 VAC +/- 20%, 24 VA, 50/60 Hz, Floating -non-grounded, and

the controller must sustain a 40ms power outage before resetting.

Input

Description

Control

Term

Supply Controller Power X01 1-2

I/O Functionality

STD

Contact De-bounce

Times are not adjustable and are for information only. .

Dig Input #

Delay Time

1 50

ms

2 15

sec

3 15

sec

4 2

sec

5

2 sec - Closed

.5 sec - Open

6 50

ms

7 50

ms

STD

Combine MOL FOL

into a common digital input called Motor Overload. Overload contact

current must be minimum 17vdc and 5 ma.

ENH

Remote Start / Stop

using a single contact

.

Summary of Contents for R110IU-10

Page 5: ...5 S3 Intellisys Controller Operating Instructions...

Page 6: ...6 Software Navigation...

Page 7: ...7 Eiger Controller Fault Indicators 020 Tr Motor PTC Open High Motor Temperature...

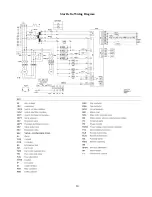

Page 14: ...14 Star Delta Wiring Diagram...

Page 15: ...15...

Page 16: ...16 Soft Start Wiring Diagram...

Page 17: ...17...

Page 18: ...18 Line Start Schematic...

Page 19: ...19...

Page 20: ...20 Process and Instrumentation Diagram...

Page 21: ...21...

Page 28: ...28 Maintenance...

Page 29: ...29 Maintenance...

Page 30: ...30 Maintenance...

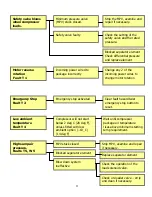

Page 31: ...31 S3 Controller Input Output Overview AI Analog Input DI Digital Input DO Digital Output...

Page 45: ...45 Standard S3 Menu Structure and Parameters Table 12...

Page 46: ...46 Standard S3 Menu Structure and Parameters Table 12...

Page 47: ...47 Standard S3 Menu Structure and Parameters Table 12...

Page 49: ...49 Modbus Register Listing...

Page 50: ...50 Table 13 Modbus Register Listing...

Page 52: ...52 Appendix 1 Thermistor 2ATT 34 to 124 C 255 F Air end Discharge...

Page 53: ...53...

Page 54: ...54...

Page 55: ...55...

Page 56: ...56...

Page 57: ...57...

Page 58: ...58 General Specifications for Eiger Packages...

Page 59: ...59...

Page 60: ...60...

Page 61: ...61...

Page 62: ...62...

Page 63: ...63...

Page 64: ...64...

Page 65: ...65...

Page 66: ...66...

Page 67: ...67...

Page 68: ...68...

Page 69: ...69...

Page 70: ...70...

Page 71: ...71...

Page 72: ...72...

Page 73: ...73...

Page 74: ...74...

Page 75: ...75...

Page 76: ...76...

Page 77: ...77...

Page 78: ...78...

Page 79: ...79...