EP20-XXXXX-XXX-XXX (en)

Page 25 of 44

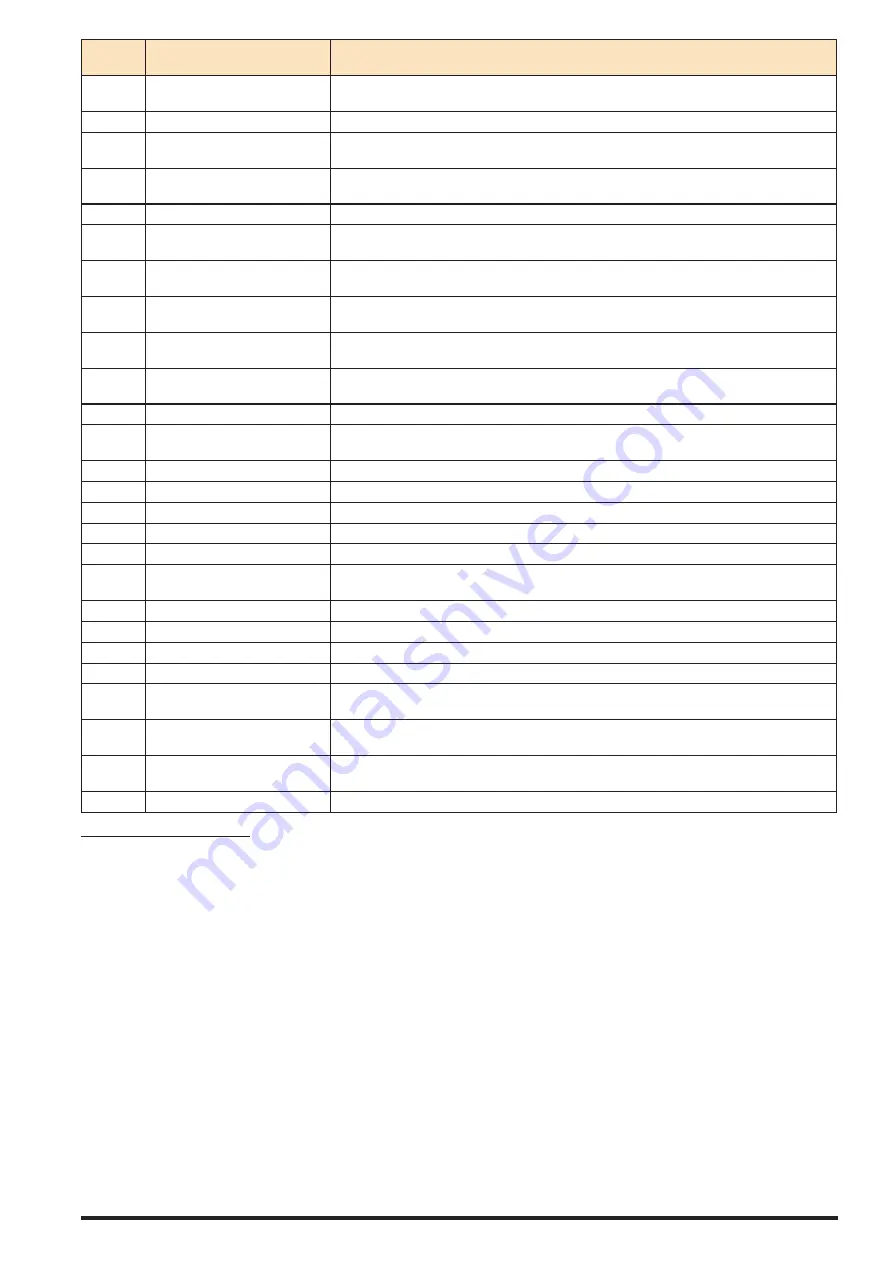

Parame-

ter

Description

Function

565

Pulse Output Max Freq #29

Set the maximum frequency for terminal 29, corresponding to the output variable selected in pa-

rameter 563.

540

Function Relay

Define relay functions using 540.0 and 540.1 (2 relays available).

610

Terminal 53 Low Voltage

Enter the low voltage value (Default 0.07V). This corresponds to the minimum reference value of 0

Hz.

611

Terminal 53 High Voltage

Enter the high voltage value (Default 10V). This correspond to the maximum reference value of 84

Hz.

612

Terminal 53 Low Current

Enter the low current value (Default 4mA). This correspond to the minimum reference value of 0 Hz.

613

Terminal 53 High Current

Enter the high current value (Default 20mA). This correspond to the maximum reference value 84

Hz.

620

Terminal 54 Low Voltage

Enter the low voltage value (Default 0.07V). This corresponds to 0% of torque limit defined by par.

416 when par. 420 is set to [6].

621

Terminal 54 High Voltage

Enter the high voltage value (Default 10V). This corresponds to 100% of torque limit defined by par.

416 when par. 420 is set to [6].

622

Terminal 54 Low Current

Enter the low current value (Default 4mA). This corresponds to 0% of torque limit defined by par. 416

when par. 420 is set to [6].

623

Terminal 54 High Current

Enter the high current value (Default 20mA). This corresponds to 100% of torque limit defined by

par. 416 when par. 420 is set to [6].

650

Terminal 42 output (mA)

Select the function of Terminal 42 as an analog current output.

651

Terminal 42 output min scale

Scale the minimum output of the selected analog signal at terminal 42, as a percentage of the maxi-

mum signal value.

652

Terminal 42 output max scale

Scale the maximum output of the selected analog signal at terminal 42.

830

Protocol

Select the protocol to be used. Select [2] for Modbus RTU.

831

Address

Enter the address for the drive port. Valid range: 1 - 126.

832

FC Port Baud Rate

Select the baud rate for the drive port.

833

Parity / Stop Bits

Set Even / Odd / No parity.

1312

Comparator Value (0-9)

Set trigger level for the variable that is monitored by this comparator. It allows to optimize dead-

head settings or leak detect filter time.

1502

KWH Counter

Read only display of KWh Counter.

2310

Maintenance Item (0-5)

Set the item to be associated with the preventive maintenance event.

2311

Maintenance Action (0-5)

Set the action to be associated with the preventive maintenance event.

2312

Maintenance Base (0-5)

Set this parameter to running hours / Operating hours / Date and Time

2313

Maintenance Interval (0-5)

Set the interval associated with the current preventive maintenance event. This parameter used only

if parameter 2312 is set to running hours / Operating hours.

2314

Maintenance Time and Date (0-5)

Set the Date and Time for next maintenance occurrence if the preventive maintenance event is

based on Date / Time.

2315

Rest Maintenance Word

Set this parameter to [1] to rest maintenance time. This parameter changes back to [0] when pressing

OK.

2316

Maintenance Text (0-5)

Maintenance text associated with parameter 2310 or parameter 2311 written on LCP.

9.3. VFD Smart Setup

When the VFD is powered on for the first time, it will automatically start up in “Smart Setup” mode to properly configure the

VFD parameters for the desired language, motor size, motor type, and type of thermal protection. This setup program will only

need to be completed once and it will have the following steps:

1. Select language - Choose desired language.

2. Select motor - Choose appropriate motor size (5.5 kw for 2" pump).

3. Select motor type – Choose “Black” for ordinary motor or “Red” for hazardous motor.

Use the VFD keypad to navigate the smart setup program. Use the “right arrow” to move to the next screen. For screens with

informational text only, press “OK” to move to the next screen. To change a parameter option (for example language), press “OK”

to highlight the parameter, use the “up or down arrows” to change the selection to the desired parameter, and then press “OK”

again to deselect that parameter before moving on to the next screen. Use the “left arrow” to navigate backwards through the

program if needed. When the setup program is complete, the VFD is properly configured for use.

In the event that the “smart setup” program was setup incorrectly or needs to be re-run, then this can be accessed by pressing

the “Quick Menu” button on the VFD keypad and selecting option “Q4 Smart Setup”.