43

Instructions for the installer

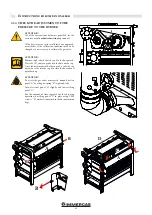

ADJUSTING SCREW

MAXIMUM POWER

ADJUSTING SCREW

MINIMUM POWER

Follow this procedure to adjust the other modules

as well.

If the measured flow rate is too low, make sure the supply and draining

systems (the supply and draining pipes) are not obstructed.

If they are not obstructed, make sure the burner and/or exchanger

are not dirty.

C) Completing basic calibration.

- Check CO

2

values at the minimum and maximum flow rate.

- Touch up if necessary.

For smooth operation, calibrate the CO

2

values taking

care to observe the values in the table.

- Close the cap for the flue inspection point back up.

NOTE: do not force the adjusting screw limit switch

limits.

A) Adjustment at maximum power.

- Unscrew the closing cap for flue exhaust analysis point.

- Place the analyser probe inside the flue analysis point.

- Make burner 1 operate at max power, following the procedure

illustrated below in "chimney sweep function " (100 % CASC

MANUAL).

- Make sure that the CO

2

level falls within the values indicated in the

"Nozzle pressure" table.

- Possibly correct the value by turning adjusting screw

"A"

CLOCKWISE

to decrease it and COUNTER-CLOCKWISE to increase it.

B) Adjustment at minimum power.

- Make burner 1 operate at min power, following the procedure

illustrated below in "chimney sweep function " (10 % CASC

MANUAL).

- Make sure that the CO2 level falls within the values indicated in the

"Nozzle pressure" table.

- Possibly correct the value by turning adjusting screw

"B"

CLOCKWISE

to increase it and COUNTER-CLOCKWISE to decrease it.