9

Technical characteristics and dimensions

2

TECHNICAL

CHARACTERISTICS AND

DIMENSIONS

2.1 TECHNICAL CHARACTERISTICS

- Heat generator, to heat Low Nox condensation gas

- Comprised of a heat module designed to operate on its own or in a

set

- Can be set up directly outside (IP X5D)

- Low water content

- High response speed to load changes

- Single flue exhaust that can be positioned on 3 sides

- Unified flow and return hydraulic manifolds

- Comprised of 4 or more heating elements (between 4 and 8),

aluminium/silicon/magnesium casting

- Including total irradiation premixing modulating burners

- None of the heating elements have hydraulic cut-off devices

- Single gas supply pipe

- Modulated power between 22 ÷ 108 kW/element.

TEMPERATURE CONTROL DEVICES:

- ROOM NTC sensor (every heating element)

- Room Limit Thermostat (every heating element)

- Flow NTC sensor (General)

- Return NTC sensor (General)

- Approved safety thermostat (To be ordered and installed on in parag.

3.8)

- GCI global flow probe.

POP-UP control panel composed of:

- ON-OFF switch see parag. 3.25

- TGC boiler thermoregulation/manager

- GCI (internal cascade management board)

- Protection fuses

- Any limit thermostats

- Fan air pressure switch

- Condensation water level sensor

- Gas pressure switch

- Exhaust pressure switch (anti-obstruction).

- The entire heating unit is equipped with global temperature control

NTC sensors on the flow and return manifolds.

-

Integral insulation with non-allergenic synthetic wool.

- Total premix burner, modulating, with "metal foam" radiation

combustion chamber. Premixing in the fan. Automatic separating

backflow diaphragm from the combustion chamber.

- Sound emissions at maximum power below 49 dBA.

- Operation during heating: determining the instantaneous power

through a control microprocessor, with preset comparison parameters

between requested temperature (or calculated by the outdoor

thermoregulation) and global flow temperature.

- Logic of operation:

- Possibility of controlling the power of the single heating elements

for calibration and/or assistance with reserved access code.

- D.H.W. production through priority NTC probe, to control the

storage tank load through a pump or three-way deviator valve

through the supplied TGC thermoregulator.

- Possibility of controlling the power of the single heating elements.

- Heat request control: temperature setpoint and modulation level.

- Monitoring the state of operation and temperatures.

- Alarm notification.

- Parameter setting.

- Control relay to switch on a pump at a fixed speed.

- Analogue 0÷10V output to control a modulating pump.

- Emergency operation: this allows you to avoid the system from

stopping due to an interruption in communication with the adjusting

system or possible remote management of the control unit:

- The possibility of selecting the emergency temperature through

supplied "Constant Setpoint" heating elements: 70°C, maximum

power 50%.

- Alarm management.

-

Alarm reset input.

-

Alarm notification Relay.

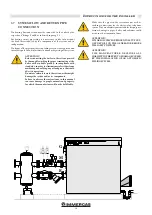

- Condensation collection tray with stainless steel exhaust trap.

- Easily removable integral panelling comprised of oven-painted steel

panels suitable for outdoor installation.

- Condensation collection tray with stainless steel exhaust trap and flue

chamber.

- Incorporated deaerator.

The request for heat can be generated by the TGC thermoregulation/

manager or alternatively by the GCI (internal cascade management

board).

The management logic envisions simultaneous operation of the

maximum number of heat elements, so as to always obtain the

maximum efficiency. Since it guarantees the maximum exchange area

based on the delivered power. The elements are made to operate so as

to equally divide the operating time.

The hot water that is produced is pushed by the pump located on the

return of the primary ring to the flow of the hydraulic separator. From

here a second pump (system - see suggested diagrams) will distribute to

the various utilities. From the system, return the cooled water is taken

in by the pump on the return, through the hydraulic separator, to start

the cycle towards the generator again.